Ultrasonic Level Meter

The instrument has a brand-new signal processing technology, with the characteristics of safety, cleanliness, high accuracy, long life, stability and reliability, convenient installation and maintenance, and simple reading. It is widely used in petroleum, chemical industry, water treatment, water conservancy, steel, coal mine, electric power and food processing industries, and is suitable for various fields such as acid, alkali, salt, anticorrosion, high temperature and explosion protection. It can be connected with various brands of PLC systems or secondary control systems through 4 ~ 20 mA or RS 485 (Modbus protocol) to provide real-time liquid level data for industrial. automation.

It has the following distinguishing advantages:

- Unaffected by the target material’s color, shape or physical composition

- Non-contact measurement for difficult liquids

- Temperature-compensated signal for improved accuracy

- Calibration without filling or discharging

- Self-cleaning effect due to vibrating sensor diaphragm

- Detection is not affected by accumulation of dust or dirt.

- Simple installation and operation

Working Principle

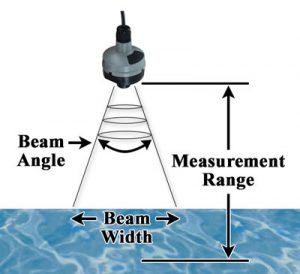

As the name indicates, ultrasonic / level sensors measure distance by using ultrasonic waves.

The sensor head emits an ultrasonic wave and receives the wave reflected back from the target. ultrasonic / level sensors measure the distance to the target by measuring the time between the emission and reception.

An optical sensor has a transmitter and receiver, whereas an ultrasonic / level sensor uses a single ultrasonic element for both emission and reception. In a reflective model ultrasonic / level sensor, a single oscillator emits and receives ultrasonic waves alternately. This enables miniaturisation of the sensor head.

Key Feature

- Stable and reliable: We select high-quality modules from the power supply part in circuit design, select highly stable and reliable devices for the procurement of key components, and can completely directly replace foreign imported instruments.

- Software technology: Acoustic intelligent technology software can perform intelligent echo analysis without any debugging and other special steps, and has the function of dynamic thinking and dynamic analysis.

- High accuracy: The acoustic intelligent technology owned by our company greatly improves the accuracy of ultrasonic level meter, the accuracy of liquid level reaches ± 0.3%, and has the field anti-interference function.

- Low failure rate, easy installation and maintenance: This instrument is a non-contact instrument and does not have direct contact with liquid. Therefore, the failure rate is low. Instrumentation provides a variety of installation methods and can be fully calibrated through this manual.

- Multiple protection: The protection level of instrument reaches IP65; the circuit parts have isolation protection function, respectively, so as to prevent short circuit, lightning strike and other damage to the whole set of instrument.

Application Range

- Food and beverage

- Water and wastewater

- Fuel, chemicals and oils measurement

- Slurries and solids

- Open channel flow measurement

- Storm water runoff

- Pond or River Level Monitoring

Technical Specification

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Range

|

5、8、10、12、15m

|

2 |

Blind Zone

|

<0.4-0.5m(different for range)

|

3 |

Measure Error

|

0.3%F.S

|

4 |

Display

|

OLED

|

5 |

Display Resolution

|

1mm

|

6 |

Frequency

|

20~350KHz

|

7 |

Power

|

12-24VDC

|

8 |

Power Consumption

|

Power consumption

|

9 |

Output (optional)

|

4~20mA RL>600Ω(standard) 1~5V\1~10V RS485 2 NPN 2 relays (AC: 5A 250V DC: 10A 24V)

|

10 |

Material

|

ABS

|

11 |

Dimension

|

Φ92mm×198mm×M60

|

12 |

Electrical Interface

|

M20 X 1.5

|

13 |

Installation

|

M60X2 or ¢61MM

|

14 |

Operating Surroundings

|

normal temperature, normal pressure

|

15 |

Protection Degree

|

IP65(others optional)

|