26G Pulse Radar Level Meter

Radar sensors are affected by different variables than other level sensors. Radar level transmitters are affected less by temperature than ultrasonic sensors, improving consistency and accuracy. Radar level sensors are also well suited for specialty applications, such as working in a vacuum, or in higher pressures (as long as the housing can handle it). Radar sensors are also less affected by foam, vapors, powders, and dust that can interfere with signals on ultrasonic sensors and lead to erroneous readings. This can make radar sensors a better choice for these applications.

It has the following distinguishing advantages:

- Non-contact, maintenance-free measurement

- Not affected by medium properties like density and conductivity, in bulk solids also unaffected by filling noise and dust

- Freely adjustable measuring range

- For high temperatures up to +450°C/+842°F

- It affected less by temperature than ultrasonic sensors, improving consistency and accuracy

- Radar level meters are also well suited for specialty applications, such as working in a vacuum, or in higher pressures (as long as the housing can handle it)

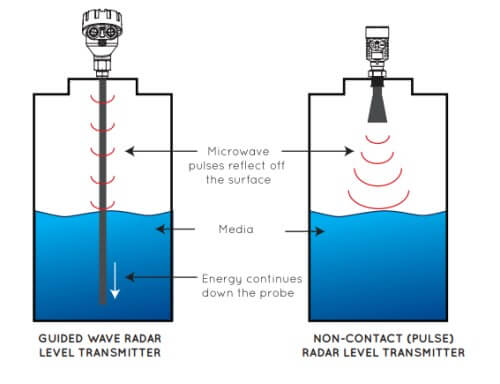

Working Principle

The extremely narrow microwave pulse emitted by the antenna on radar level instrument can travel at the speed of light and part of its energy, which is reflected off the surface of target medium, is received by the very same antenna. The time lapse between pulse emission and reception by the antenna is proportional to the distance between the surface of target medium and the reference point on antenna. However, due to the fact that the electromagnetic wave is transmitted at extremely high speed, which leads to the tiny time lapse (nanosecond level) and makes it difficult to be identified, JERD810 series of radar level instrument have adopted a special demodulation technology, enabling itself to detect the time lapse between pulse emission and reception correctly, and eventually generate accurate measurement result.

Key Feature

- Small beam angle, which centralize energy, make JERD800 high ability of anti-jamming, hence high accuracy and reliable.

- Small antenna size, easy to mount and easy to equip extra dust protection

- Small blind zone, good accuracy even for small

- Shorter wave-length, suitable for the measurement of powder, grain and etc.

- The guided wave radar level instrument, with pulses as its working tool and extremely low emission power, can be mounted on various metal or nonmetal vessels, harmless towards the environment and human beings.

Application Range

Equipped with advanced microprocessor and unique Echo Discovery echo processing technology, the radar level instrument can be used under various hazardous process conditions

Find out more about our products

Our electromagnetic flowmeters are optimised for customers and applications for the precise flow measurement of virtually all pumpable media.

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Application

|

Liquid, especially for highly corrosive liquids

|

2 |

Measuring Range

|

10 m

|

3 |

Repeatability

|

±5mm

|

4 |

Process Temperature

|

-40~130℃

|

5 |

Process Pressure

|

(-0.1~0.3)MPa

|

6 |

Frequency Range

|

26G

|

7 |

Signal Output

|

4~20mA/HART/Modbus

|

8 |

Power

|

two wire(DC24V), four wire(DC24V/AC220V)

|

9 |

On-site Display

|

LCD(Optional)

|

10 |

Housing

|

selective

|

11 |

Process connection

|

screw/flange(selective)

|

12 |

Antenna

|

Rod(PTFE)

|

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Application

|

Liquid, temperature pressure slightly corrosive liquid

|

2 |

Measuring Range

|

30 m

|

3 |

Repeatability

|

±3mm

|

4 |

Process Temperature

|

-40~130℃ / -60~250℃

|

5 |

Process Pressure

|

-0.1~0.4 MPa

|

6 |

Frequency Range

|

26G

|

7 |

Signal Output

|

4~20mA/HART/Modbus

|

8 |

Power

|

two wire(DC24V), four wire(DC24V/AC220V)

|

9 |

On-site Display

|

LCD(Optional)

|

10 |

Housing

|

selective

|

11 |

Process connection

|

screw/flange(selective)

|

12 |

Antenna

|

Rod(PTFE)

|

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Application

|

liquids,use for highly erosive liquids

|

2 |

Measuring Range

|

20 m

|

3 |

Repeatability

|

±3mm

|

4 |

Process Temperature

|

-40~150℃

|

5 |

Process Pressure

|

-0.1~0.5 MPa

|

6 |

Frequency Range

|

26G

|

7 |

Signal Output

|

4~20mA/HART/Modbus

|

8 |

Power

|

two wire(DC24V), four wire(DC24V/AC220V)

|

9 |

On-site Display

|

LCD(Optional)

|

10 |

Housing

|

selective

|

11 |

Process connection

|

screw/flange(selective)

|

12 |

Antenna

|

cone-shape plating (PTFE/Stainless steel316L)

|

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Application

|

solid, strong dew, dust, crystal

|

2 |

Measuring Range

|

80 m

|

3 |

Repeatability

|

±15mm

|

4 |

Process Temperature

|

-40~130℃ / -60~250℃

|

5 |

Process Pressure

|

-0.1~4.0 MPa

|

6 |

Frequency Range

|

26G

|

7 |

Signal Output

|

4~20mA/HART/Modbus

|

8 |

Power

|

two wire(DC24V), four wire(DC24V/AC220V)

|

9 |

On-site Display

|

LCD(Optional)

|

10 |

Housing

|

selective

|

11 |

Process connection

|

screw/flange(selective)

|

12 |

Antenna

|

Horn(Stainless steel316L)

|

| # |

Item Name |

Parameter Values |

|---|---|---|

1 |

Applicable Medium

|

Food and wine industry

|

2 |

Caliber Range

|

DN15-DN200

|

3 |

Lining Type

|

PTFE, F46, PFA

|

4 |

Electrode Type

|

316L, Ha B, Ha C, titanium, tantalum, platinum-iridium alloy, stainless steel tungsten carbide

|

5 |

Pressure Range

|

0.6-4.0Mpa

|

6 |

Temperature Range

|

-25~80℃

|

7 |

Accuracy

|

±0.5%

|

8 |

Protection level

|

Sensor IP65\IP67\IP68 (optional), converter IP65

|

9 |

Output Type

|

Frequency, pulse, 4-20mA, RS485, Modbus protocol; Hart protocol (optional), Profibus DP (optional)

|

10 |

Power Supply

|

85~250V, 45~63Hz, 20VDC --- 36VDC

|