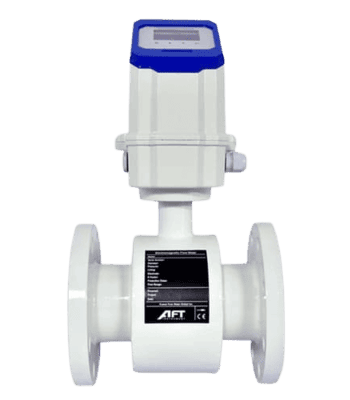

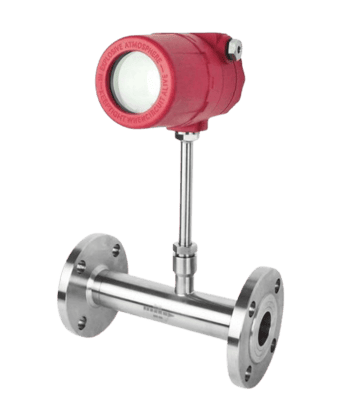

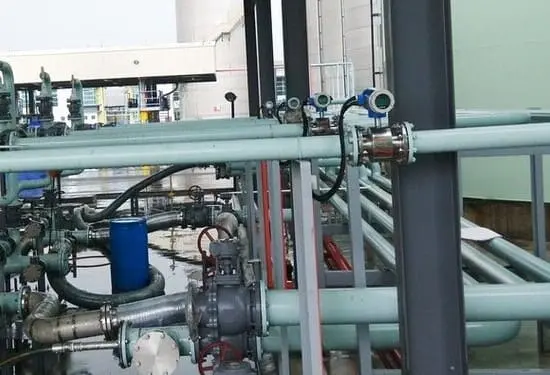

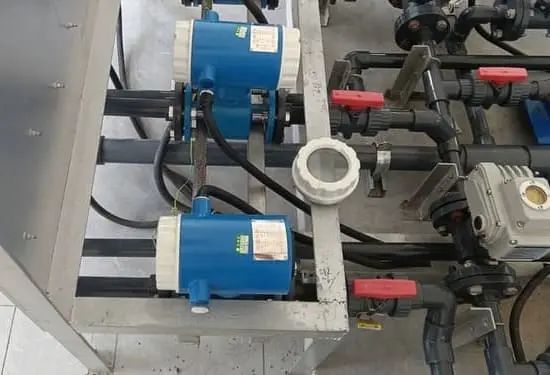

Innovative Design for Demanding Industrial Needs

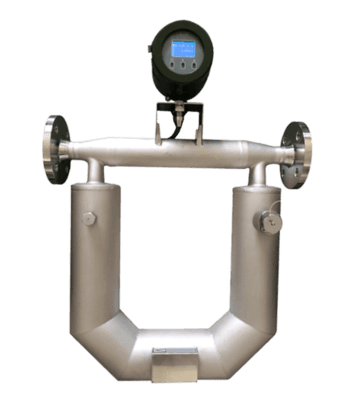

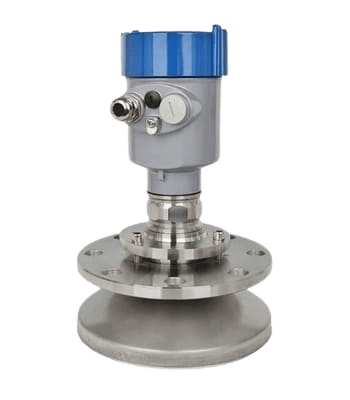

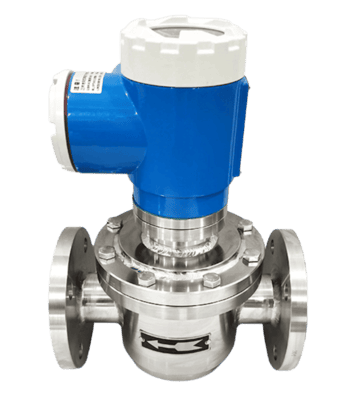

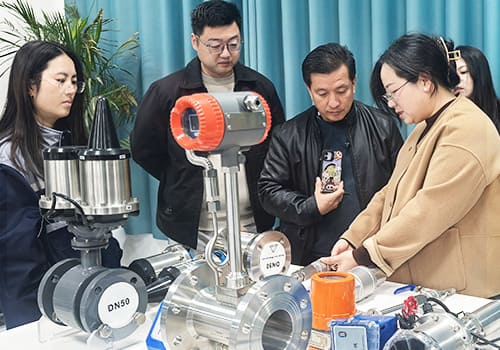

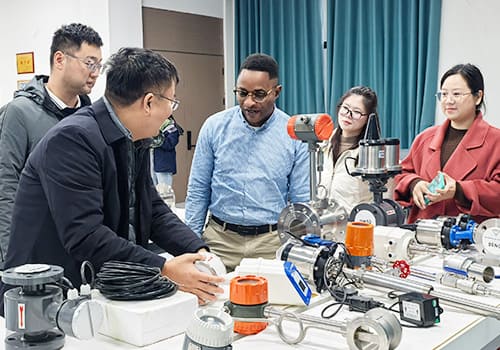

Precision Instruments Built Through Engineering Excellence

Our manufacturing and R&D systems are designed to deliver instrumentation that performs with repeatable, long-term precision in demanding industrial environments. From advanced engineering design to tightly controlled production, and from high-accuracy calibration to full quality traceability, we ensure each flow meter meets the expectations of global enterprise users.