CE, SIL-3 & ATEX Certifications

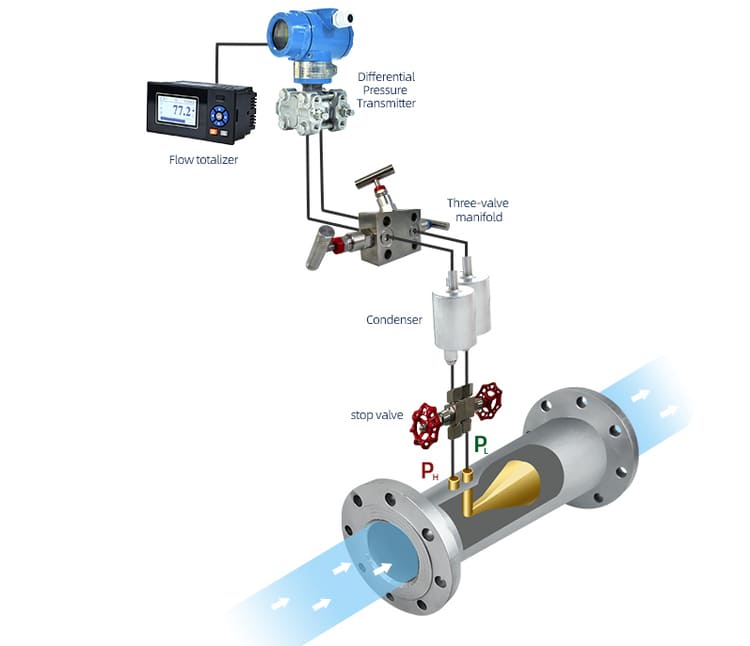

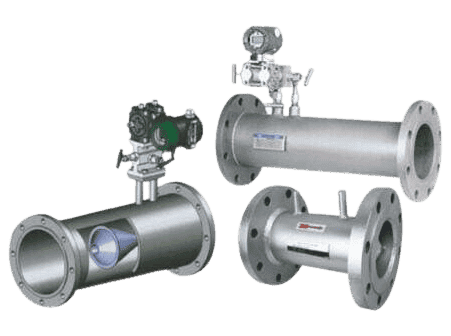

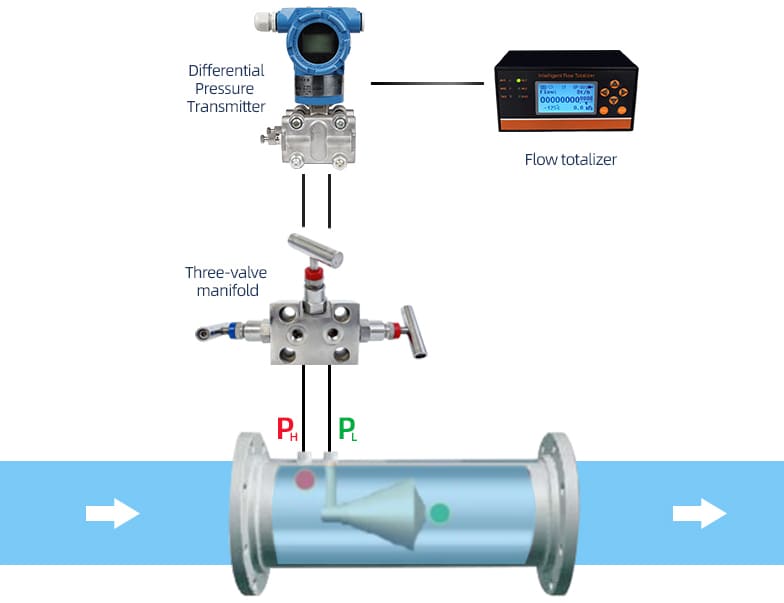

V-Cone Flowmeter

DP flowmeter for limited installation space

Precision Level Measurement Within Reach

Explore Our V-Cone Flowmeters

Technical Specifications

- Product Name: V-Cone Differential Pressure Flowmeter

- Structure Types: Pipe-mounted, Clip-mounted, Insert-mounted

- Accuracy: ± 0.5% (special requirements can achieve 0.3%)

- Repeatability: Better than ± 0.1%

- Rangeability: 10:1 typical, up to 30:1

- Fluid Types: Oil, water, steam, air, natural gas, nitrogen, coke oven gas, etc.

- Pipe Sizes: Pipe: 1/2″ to 120″, Clip: 1/2″ to 10″, Insert: 10″ to 120″

- Pressure Loss: Permanent pressure loss smaller than orifice plate; stable and minimal

- Reynolds Number Range: Max: 5 million, Min: 8000 or even lower

- Operating Temperature: Up to 850°C (higher with special materials)

- Max Operating Pressure: 42 MPa (higher with special materials)

- Signal Stability: Stable signal with low frequency, low amplitude fluctuations

- β Value Range: Standard β value: 0.350 – 0.900, customizable depending on application

- Working Fluid Temperature: Can measure fluids from low temperature to supercritical

- Installation Requirements: Upstream: 0-3D, Downstream: 0-1D straight pipe section

Main performance features

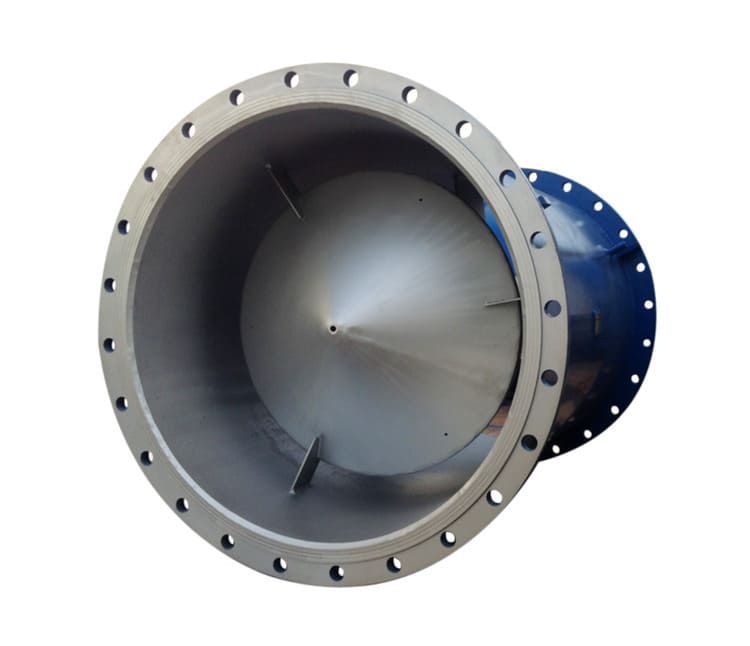

Precision Geometry Backed by Advanced Flow-Mechanics Research

CFD-Guided Profile Design

The cone geometry is refined through fluid-dynamic simulations to achieve uniform velocity distribution and stable differential-pressure generation under diverse flow profiles.

DP Signal Stability Analysis

Signal behavior is modeled across varying Reynolds numbers to ensure consistent performance during load changes, density shifts, and upstream turbulence.

Thermal-Mechanical Evaluation

Material selections and body structures are validated under simulated temperature and pressure extremes to support long-term field reliability.

Application-Driven β-Ratio Optimization

β-ratio ranges are engineered to match pipeline size, media composition, and operating conditions, ensuring accurate DP response across the meter’s full range.

Manufacturing Excellence

Fabrication, assembly, and testing are optimized to protect performance under real pipeline conditions.

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Precision Flow Measurement Starts Here