CE, SIL-3 & ATEX Certifications

Orifice Flow Meters

Stable, standards-based flow measurement engineered for industrial reliability

Our orifice flow meters are engineered to generate stable differential pressure for accurate flow determination across a broad range of industrial applications. With design and manufacturing aligned to ISO 5167 / GB/T 2624 standards, each meter provides predictable behavior, long service life, and strong integration with DP transmitters and automation systems.

Request Your Free Quote Now

Precision Flow Monitoring Built on Proven DP Measurement

Explore Our Orifice Flowmeters

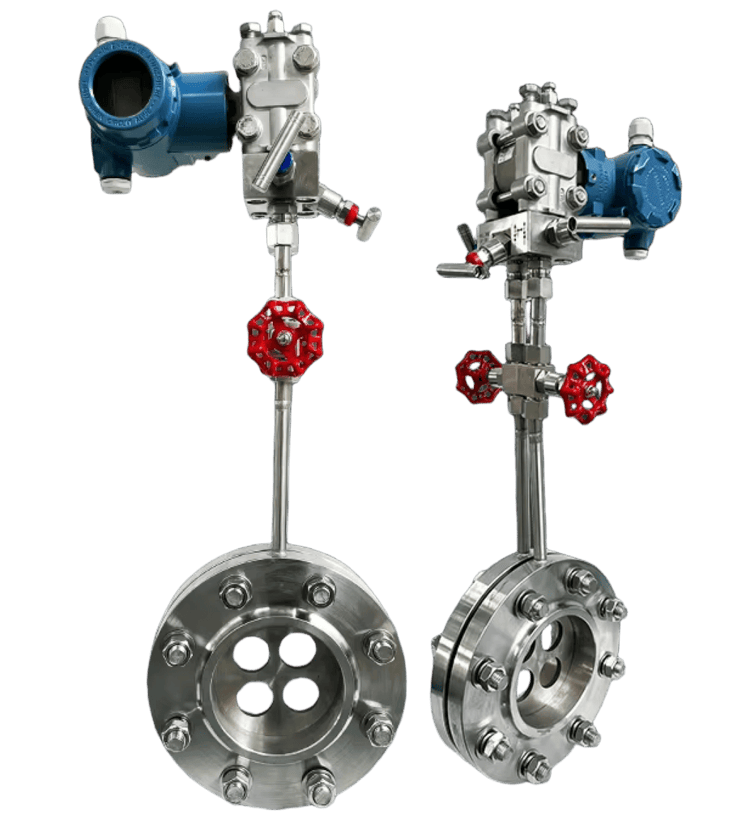

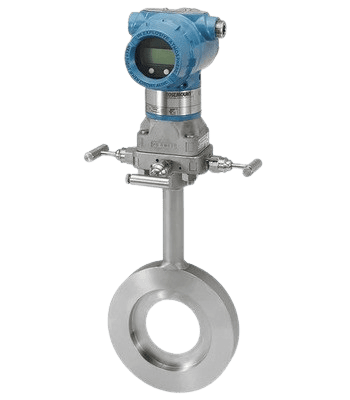

Integrated Orifice Flowmeter

Inquiry Now

Balance Orifice Plate Flowmeter

Inquiry Now

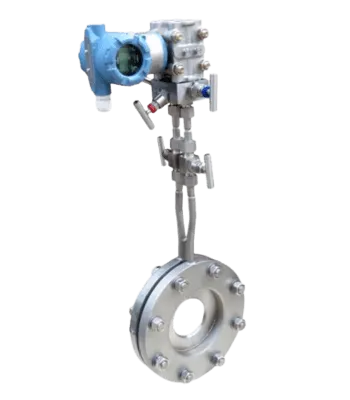

Flanged Orifice Plate Flowmeter

Inquiry Now

Direct Mount Orifice Flowmeter

Inquiry Now

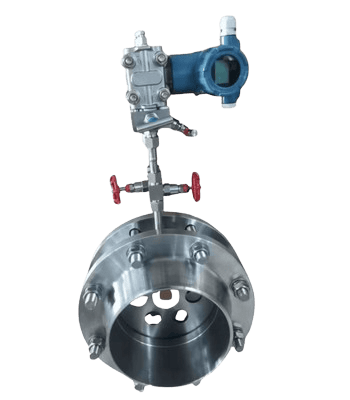

Integrated Wafer Orifice Flowmeter

Inquiry Now

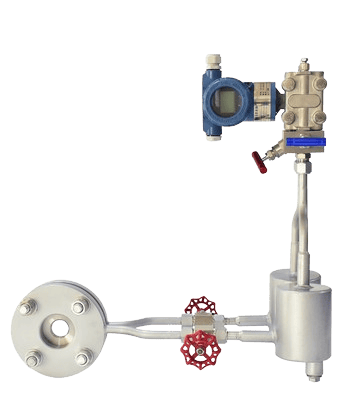

Differential Pressure Orifice Plate Flowmeter

Inquiry Now

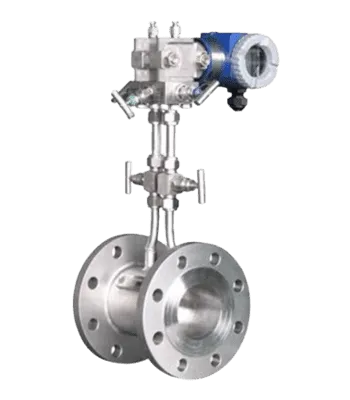

Orifice Flowmeter with Corner Taps

Inquiry Now

Integral Orifice Assembly

Inquiry NowMain performance features

R&D Design Grounded in Standardized Engineering Principles

Precision Plate Geometry

We analyze plate-edge profiles and bore dimensions using fluid-dynamic modeling to maintain stable discharge coefficients under varying conditions. This approach ensures predictable differential-pressure behavior across a wide Reynolds-number range.

Standards-Based Sizing Models

We apply ISO 5167 and GB/T 2624 design frameworks to ensure that sizing calculations, beta ratios, and installation requirements align with recognized international practices. This supports compatibility with global engineering specifications.

Controlled Surface Finishing

Our machining processes maintain surface roughness and flatness within strict tolerances to minimize flow disturbance and maintain consistent ΔP generation. Each plate undergoes uniform inspection to verify dimensional integrity.

Coefficient Stability Analysis

Through theoretical and empirical evaluation, we ensure the discharge coefficient remains predictable across operating ranges. This enhances integration with DP transmitters and control systems.

Manufactured With Precision, Verified for Performance

Manufacturing discipline ensures stable response across operating ranges.

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Precision Flow Measurement Starts Here