CE, SIL-3 & ATEX Certifications

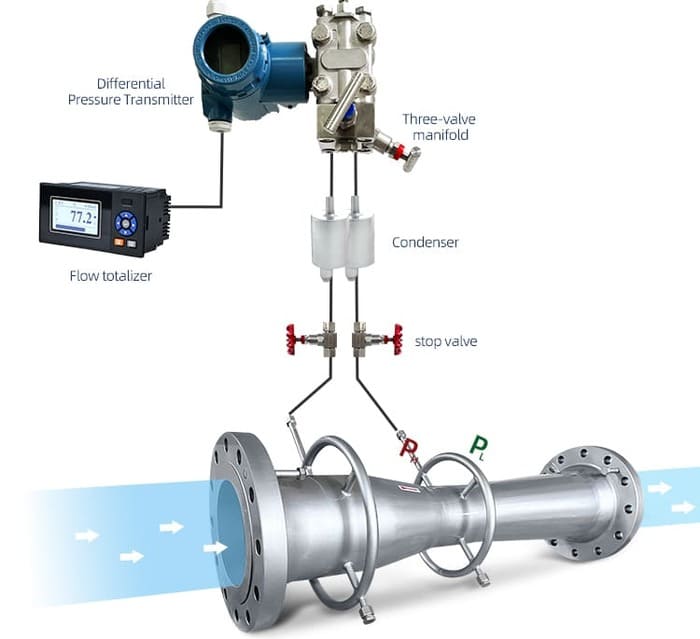

Venturi Flowmeter

Engineered for Stable, Continuous Measurement Across Industrial Tanks and Vessels

Precision Level Measurement Within Reach

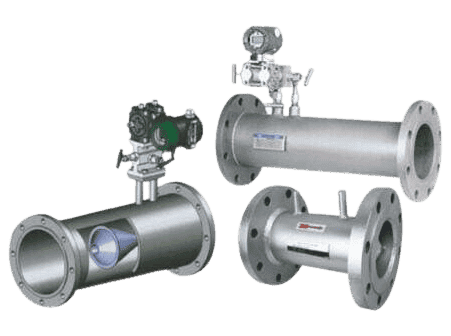

Explore Our Venturi Flowmeters

Technical Specifications

- Product Name: Venturi Differential Pressure Flowmeter

- Accuracy: ± 0.5%,+/-1%, +/-1.5%

- Flow Rate: Liquid: 0.3 ~ 10 m/s; Gas: 5 ~ 60 m/s

- Flow Rate:0.5Mpa-42Mpa

- Nominal diameter: DN3 – DN2600

- Suitable Media: Liquids, gases, steam, unclean natural gas, high wet gas, dirty fluids, strong and corrosive fluids.

- Expansion Coefficient: Meets GB/T 2624-93 standards.

- Pressure Loss: About 1/5 of the differential pressure (1/3 of the hole plate pressure loss).

- Reynolds Number Range: ReD ≥ 4103 (lower limit can be lower with higher uncertainty).

- Pressure Type: Ordinary pressure and remote flange pressure types.

- Flange Standard: National standard flange (chemical standard flange on request).

- Outflow Coefficient Stability: Best stability compared to other differential pressure flow meters.

- Applicable Fluids: Suitable for measuring gases with higher viscosity, dirty fluids, and corrosive liquids.

Main performance features

Every contour, angle, and surface engineered to enforce stable differential-pressure behavior.

Velocity-Profile Simulation

We model flow contraction and expansion to achieve a stable velocity distribution at the throat, enhancing overall measurement uniformity.

Optimized Flow Passage Geometry

Internal contouring and mirror polishing reduce turbulence and pressure loss, maintaining smooth flow contraction and recovery in real applications.

Pressure-Extraction Stability

Positive and negative pressure pathways are designed to minimize turbulence influence and provide a clean differential signal under varying flow conditions.

Load-Condition Verification

Testing across various flow rates ensures predictable signal response and preserves meter reliability under industrial fluctuations.

Built for Dimensional Accuracy and Stable Flow Behavio

Precision forming and comprehensive verification ensure Venturi reliability over time.

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Precision Flow Measurement Starts Here