Advanced Equipment & Technology

Building Precision Through Engineering-Grade Infrastructure

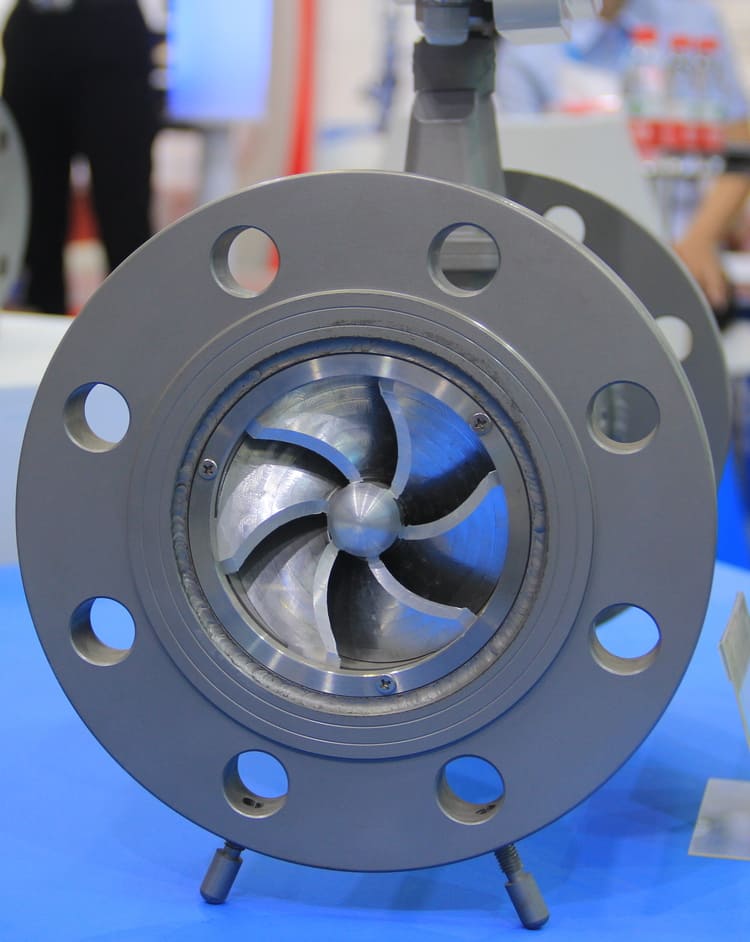

Our production environment is equipped with advanced tools that ensure stable output and high dimensional accuracy. CNC machining centers deliver precise mechanical structures, automated assembly stations improve consistency, and specialized equipment supports sensor bonding, electronic soldering, and signal testing. These investments allow us to achieve reliable product performance at scale while reducing human variability in critical steps.