Assembly Precision & Functional Testing

Calibration That Guarantees Real Industrial Accuracy

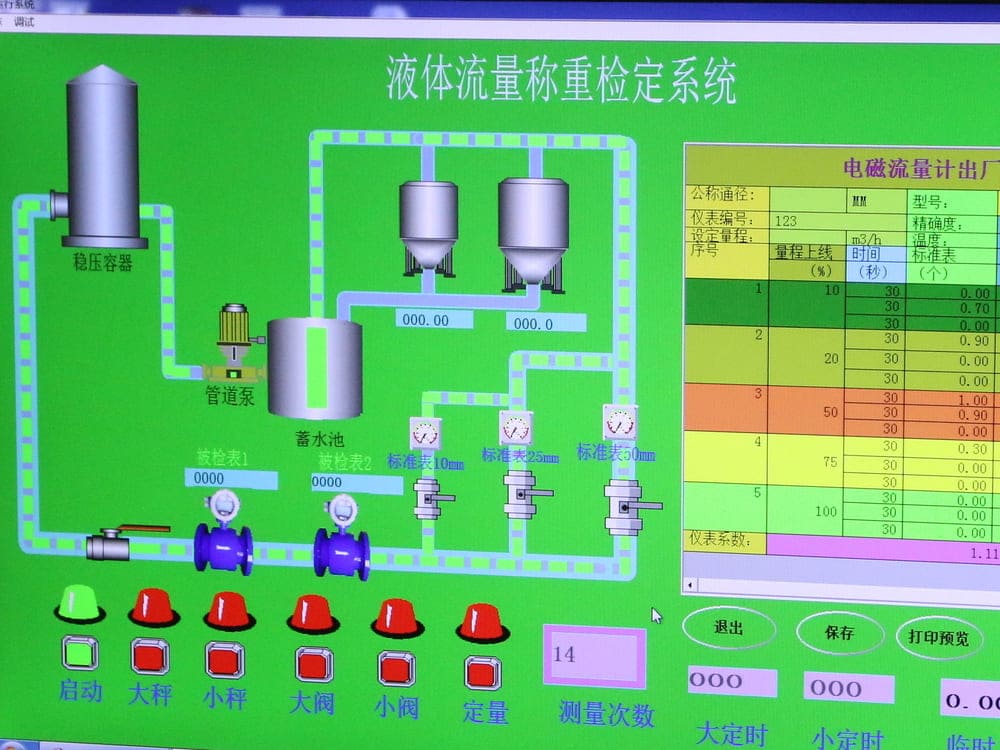

Precision calibration is the core of reliable flow measurement. Our multi-range flow rigs, reference meters, and calibration software systems ensure each device is tuned to deliver consistent performance across its entire operating range. Every calibration follows documented procedures aligned with international metrology practices, ensuring traceability, accuracy, and repeatability.