CE, SIL-3 & ATEX Certifications

coriolis Mass flowmeter

Accurate, stable, and application-ready measurement—engineered for Critical Industrial conditions

Trusted Mass Flow & Density Monitoring for Complex Fluids

Explore Our coriolis flowmeters

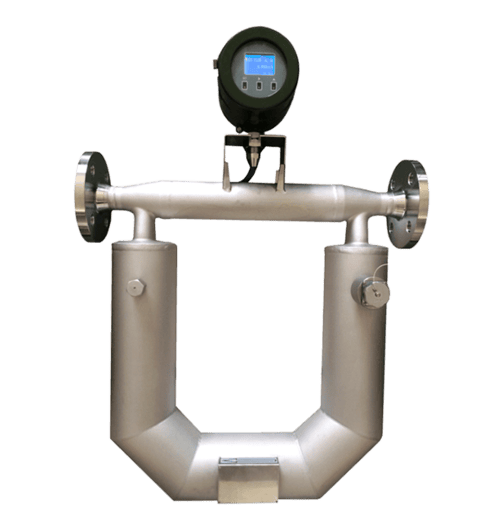

U-Shaped Coriolis Flowmeters

- Accuracy (mass): ±0.1–0.2% + ZS/MV

- Repeatability: 0.05–0.1%

- Density: 0.3–3.0 g/cm³ (±0.002 g/cm³)

- Temperature: –200…+350°C (±1°C)

- Pressure Rating: 4.0 MPa

- Wetted Material: SS316L

- Explosion-proof: Ex d [ia] IIC T6 Gb

- Ambient: –20 ~ +60°C

Triangle integral Coriolis Flowmeters

- Accuracy (mass): ±0.1–0.2% + ZS/MV

- Repeatability: 0.05–0.1%

- Density: 0.3–3.0 g/cm³

- Temperature: –50…+200°C

- Pressure Rating: 2.5–4.0 MPa

- Wetted Material: SS316L / Optional alloys

- Explosion-proof: Ex d [ia] IIC T6 Gb

- Ambient: –20…+60°C

Triangle Shape Coriolis Flowmeters

- Accuracy (mass): ±0.1–0.5% + ZS/MV

- Measuring range: typical 10:1 or 20:1

- Density: 0.3–3.000 g/cm³

- Temperature: –50…+200°C (±1°C)

- Pressure rating: 0.6–4.0 MPa

- Output options: 4–20 mA + pulse + RS485 / HART

- Explosion-proof: ExdbiaIICT6Gb

- Ambient: –40 ~ +60°C (remote)

Main performance features

R&D Framework Built on Field Data, User Requirements, and Long-Term Reliability

Symmetrical Tube Geometry Control

Each vibrating tube pair is shaped and matched to minimize asymmetrical deformation, significantly improving repeatability and long-term zero stability.

Thermal-Drift Compensation Design

Our R&D team evaluates how temperature affects tube stiffness and sensor behavior, then builds compensation curves that eliminate drift and maintain measurement integrity from cryogenic to high-temperature applications.

Low-Noise Sensor Pickup Assembly

Sensor coils are engineered to deliver clean, high-resolution phase data, even in the presence of ambient electrical noise or mechanical vibration.

Long-Term Drift Lifecycle Testing

Meters are subjected to extended-duration flow cycling and thermal cycling to validate stability and prevent performance degradation over time.

Built for Precision, Trusted in Critical Operations

Built With High-Precision Engineering, Validated With Metrological Rigor

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

A Picture's Worth a Thousand Words

Field-Tested in Real Production Conditions

Precision Flow Measurement Starts Here