CE, SIL-3 & ATEX Certifications

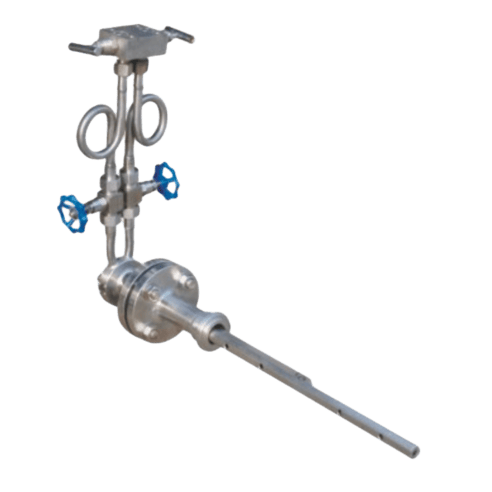

Averaging Pitot Tube Flowmeter

Engineered for Stable DP Measurement in Large Pipelines

Precision Level Measurement Within Reach

Explore Our Averaging Pitot Tube Flowmeter

Key Specifications Sheet

| Parameter | Specification |

|---|---|

| Applicable Media: | Air, gas, steam, and clean liquids |

| Insertion Length Options: | 200, 400, 600, 1000, 1500, 2000 mm (custom lengths available) |

| Measurable Velocity Range: | 0–30 m/s to 0–80 m/s (selectable), turndown ratio 1:10 |

| Accuracy: | ≤ ±1% FS |

| Output Signal: | 4–20 mA differential-pressure proportional output (two-wire system) |

| Power Supply (Transmitter): | 24 VDC (ripple < 2%) |

| Solenoid Valve Power: | 220 VAC (for back-blowing function) |

| Operating Temperature: | −40°C to +80°C (instrument body) |

| Medium Temperature: | −40°C to +121°C |

| Humidity: | ≤100% RH (non-condensing) |

| Installation Requirements: | 3D–5D upstream straight pipe section recommended |

| Calibration Frequency: | Every 12 months |

| System Configuration Options: | Speed measurement; speed + backflush; speed + static pressure + backflush; speed + static pressure + temperature + backflush |

Main performance features

Advanced Design Grounded in Applied Fluid Mechanics

Refined Aerodynamic Profile Engineering

The bullet-shaped sensor is refined to improve flow interaction, reduce flow separation, and maintain stable velocity averaging.

High-Strength Differential Pressure Stability

DP signal behavior is validated under shifting operating conditions to confirm consistent output and reduced susceptibility to flow disturbances.

Material Engineering for Harsh Conditions

Probe materials and structural components are selected and tested to withstand high temperatures, corrosive media, and long-term industrial exposure

Application-Specific Design Validation

The meter is tested against air, gas, steam, and clean liquid media to confirm compatibility and consistent performance across industries.

Precision Fabrication Supporting Measurement Confidence

High-Reliability Manufacturing for Demanding Applications

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Precision Flow Measurement Starts Here