Guided Wave Radar Level transmitter

-

High-frequency 26 GHz radar: Concentrated beam angle cuts through vapor, dust, and tank obstructions—ensuring stable signals and reliable readings.

-

True non-contact measurement: No moving parts and no contact with the medium means less maintenance, no corrosion risk, and long-term measurement stability.

-

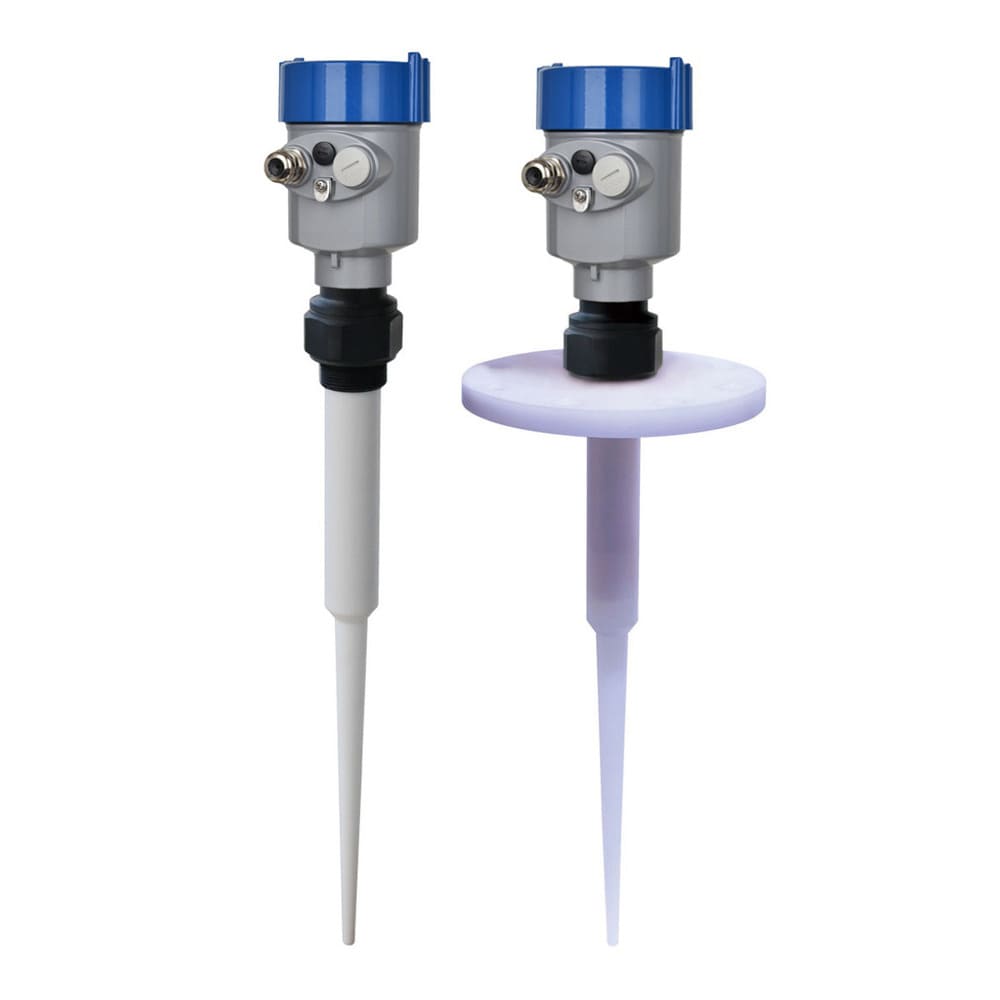

Multiple antenna designs for every application: Rod, cone, horn, and PTFE-shielded antennas support corrosive liquids, high-viscosity media, powders, and bulk solids.

-

Short blind zone: Ideal for small storage tanks and applications requiring high accuracy near the upper range.

-

Wide measurement range: From compact 10-meter vessels to tall silos up to 80 m, one platform covers nearly all level measurement needs.

-

Advanced echo processing: Smart signal interpretation separates real echoes from noise—improving reliability in dust, foam, and turbulence.

-

Built for harsh process conditions: Options support high temperatures, high pressure, heavy dust, condensation, and corrosive atmospheres.

-

Flexible installation options: Threaded or flanged connections available; fits metal or non-metal tanks without modifications.

-

Universal communication compatibility: Standard 4–20 mA, HART, and Modbus outputs integrate easily with existing control systems and PLC/DCS networks.

-

Explosion-proof and high-protection housing: Certified models allow safe use in hazardous or classified areas with gas, vapor, or dust.

General Performance

-

Technology: Guided Wave Radar (TDR)

-

Frequency: 100 MHz – 1.8 GHz

-

Measurement Range:

-

Cable probe: up to 30 m

-

Rod / coaxial probe: up to 6 m

-

-

Repeatability: ±3 mm (rod/coaxial), ±10 mm (cable)

-

Resolution: 1 mm

-

Response speed: ~0.2 s

-

Output: 4–20 mA / HART

-

Probe types: Single cable, double cable, single rod, coaxial tube

-

Dielectric constant: Works with εr ≥ 1.4

Process Conditions

-

Process temperature:

-

Standard: –40 to +130 °C

-

High-temperature: up to +250 °C (some models up to +400 °C)

-

-

Process pressure: –1 to 40 bar

-

Protection: IP65–IP68 housing

-

Power: 24 V DC (two-wire or four-wire), 220 V AC (four-wire)

Explosion-Proof Certifications

-

Ex ia IIC T6 Ga (intrinsically safe)

-

Ex d[ia] IIC T6 Gb (explosion-proof)

➤ RD701 — General Purpose Liquids & Solids (Single cable or single rod)

-

Measuring range: up to 30 m (cable), 6 m (rod)

-

Accuracy: ±10 mm

-

Process temp: –40 to +250 °C

-

Best for: general liquids, process tanks, basic solid applications

-

Applications: water, oils, fuels, solvents, powders, grains

➤ RD702 — Corrosive Medium Measurement (Full PTFE sealing cable/rod)

-

Measuring range: 20 m

-

Accuracy: ±10 mm

-

Temp: –40 to +200 °C

-

Best for: acids, bases, chemical solvents, aggressive liquids

-

Applications: chemical plants, acid/alkali tanks, corrosive process vessels

➤ RD703 — Solid Powder Measurement (Double cable)

-

Measuring range: 30 m

-

Accuracy: ±10 mm

-

Temp: –40 to +150 °C

-

Best for: powders with dust, aeration, or bridging

-

Applications: cement silos, ash bins, limestone, grain silos

➤ RD704 — Low Dielectric / Difficult Liquids (Coaxial tube)

-

Measuring range: 6 m

-

Accuracy: ±5 mm

-

Temp: –40 to +250 °C

-

Best for: low εr liquids

-

Applications: deionized water, condensate, deoxygenated water, solvents

➤ RD705 — High Temperature & High Pressure (Single cable/rod)

-

Measuring range: 15 m

-

Temp: –40 to +400 °C

-

Pressure: up to 40 MPa

-

Best for: sealed tanks, reactors, HP/HT processes

-

Applications: high-pressure boilers, chemical reactors, high-temp liquids

Liquids

-

Water, condensate, DI water

-

Hydrocarbons, oils, fuels

-

Acids, alkalis, corrosive chemicals

-

Food-grade liquids

-

Coating materials, solvents, additives

Solids / Powders

-

Plastic pellets, resin granules

-

Cement, sand, minerals, ore

-

Grain, feed, agricultural products

-

Fly ash, coal powder

-

Limestone, gypsum

Challenging Environments

-

Steam-filled vessels

-

Heavy condensation

-

Tanks with internal obstructions

-

Vessels requiring foam suppression

-

Low dielectric materials

-

Tall or narrow vessels