CE, SIL-3 & ATEX Certifications

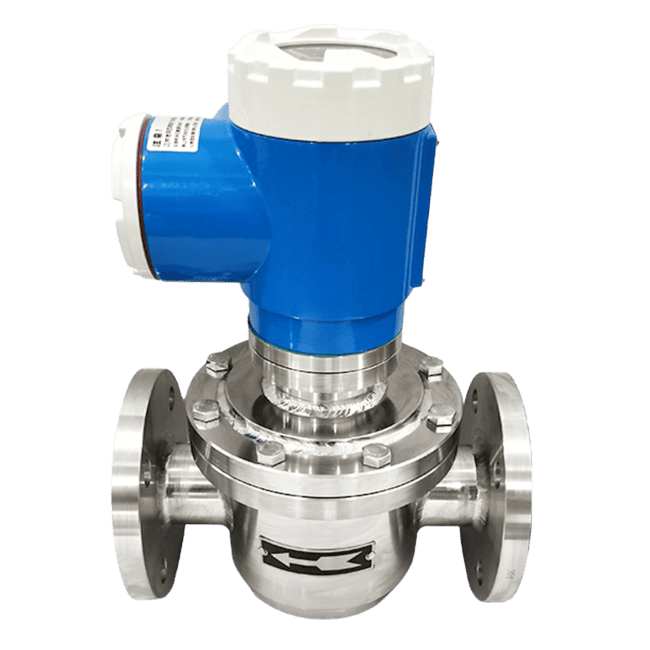

Oval Gear Flowmeter

Precise volumetric metering for High-Viscosity and Clean-Liquid Applications

Purpose-Built Options for Reliable, Repeatable Flow Monitoring

Explore Our Oval Gear Flowmeter

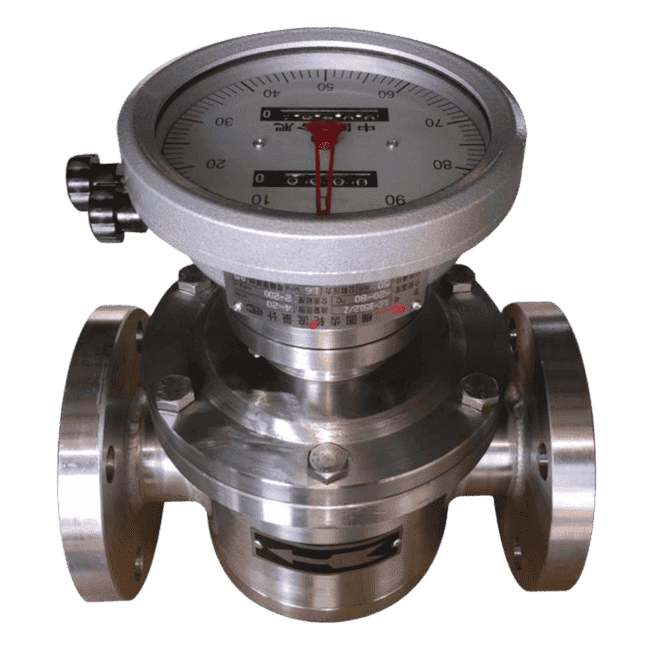

Stainless Steel Oval Gear Flowmeter

- Accuracy: ±0.5% or ±0.2%

- Viscosity: 2–8×10⁻⁶ m²/s and above

- Media: Solvents, food-grade liquids, etc

- Medium Temp: −20 to 120°C

- Output: Pulse / 4–20 mA

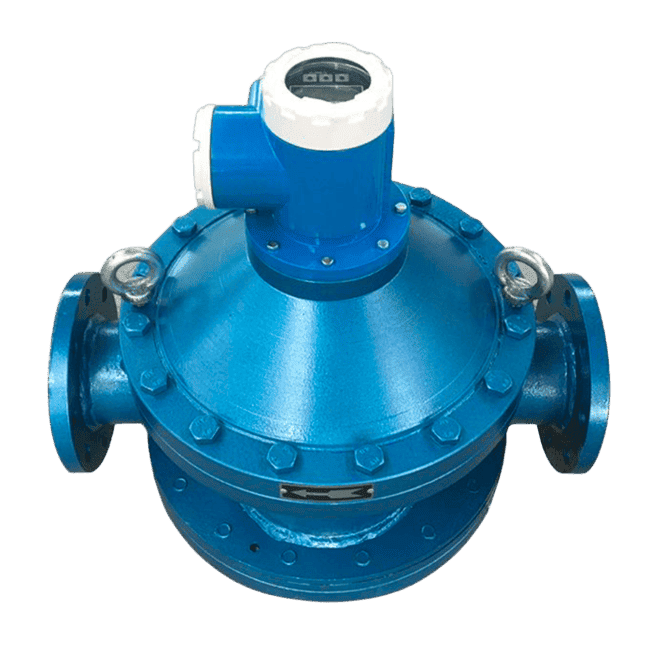

Cast Steel Oval Gear Flowmeter

- Accuracy: ±0.5% or ±0.2%

- Media: Oils, fuels, industrial liquids, etc

- Medium Temp: −10 to 120°C

- Viscosity Adaptability: Medium–High

- Output: Mechanical / Electronic

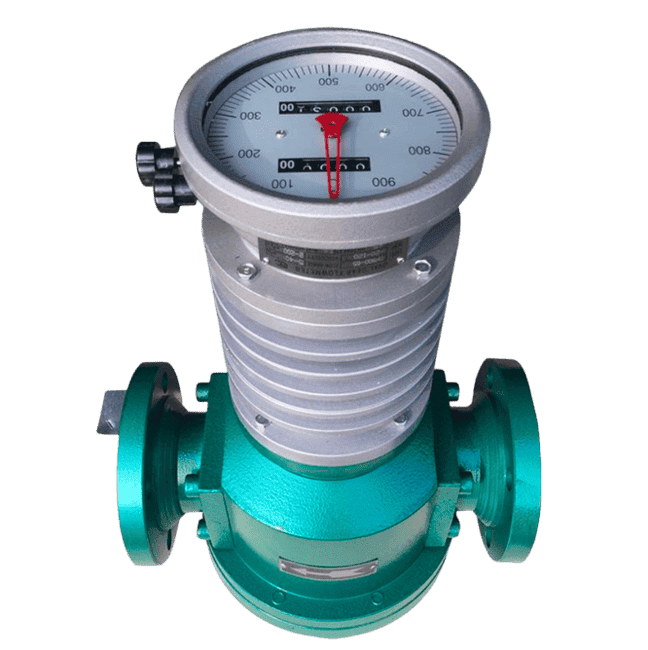

Cast Iron Oval Gear Flowmeter

- Accuracy: ±0.5%

- Media: Diesel, lubricants, light oils, etc

- Viscosity: Stable in moderate-viscosity fluids

- Medium Temp: −10–120°C

- Output: Pulse / Mechanical

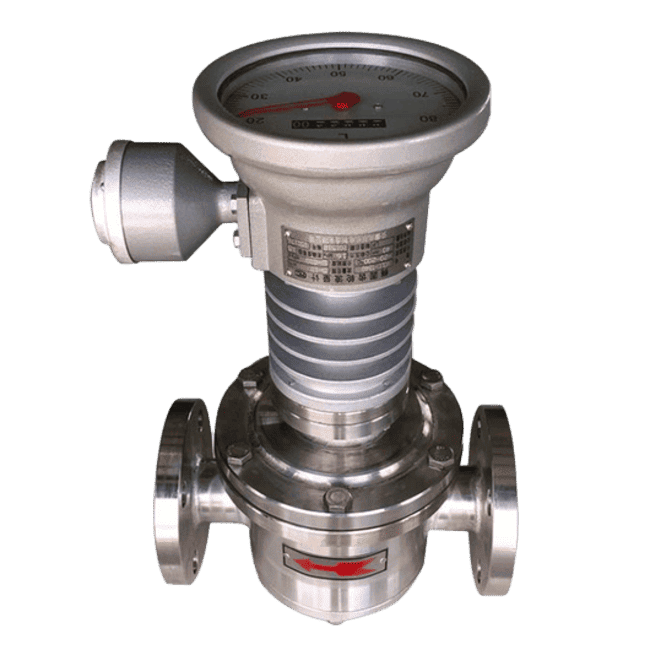

High-Temperature Oval Gear flowmeter

- Accuracy: ±0.5% / ±0.2%

- Media: Thermal oil, resin, asphalt, etc

- Medium Temp:Up to 200–300°C

- Seal Material: Reinforced high-temp seals

- Outputs: Mechanical + Pulse

High-Viscosity Oval Gear Flowmeter

- Accuracy: ±0.5%/±0.2%

- Viscosity: Up to 10,000+ mPa·s

- Media: Adhesives, resins, coatings, thick oils

- Medium Temp: −10 to 120°C

- Output: Pulse / 4–20 mA

Stainless Steel Explosion-Proof Oval Gear Flowmeter

- Accuracy: ±0.5%

- Explosion-Proof Rating: Ex d IIB T4

- Media: Fuels, solvents, flammable liquids

- Outputs: Pulse + 4–20 mA

- Display: LCD Total & Instant Flow

Main performance features

Developed to deliver predictable accuracy in demanding fluid conditions

Fluid Behavior Analysis

Gear and chamber geometry are refined based on empirical data from high-viscosity and temperature-sensitive media.

Optimized Torque and Gear Alignment

Gear rotation characteristics are engineered to maintain low friction and consistent displacement, supporting stable volumetric output.

Stable Pickup Verification

Signal modules are tested for pulse integrity, ensuring clean outputs under vibration, turbulence, or electrical interference.

Performance Curve Verification

Meters are evaluated across multiple flow points to confirm linearity, repeatability, and measurement predictability.

Measured Accuracy Starts With Controlled Manufacturing

Engineered through controlled processes and disciplined quality standards

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

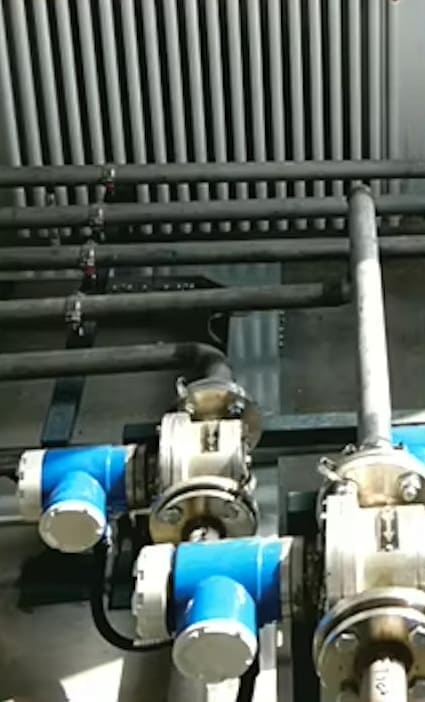

A Picture's Worth a Thousand Words

Trusted in Industrial Facilities Worldwide

Precision Flow Measurement Starts Here