CE, SIL-3 & ATEX Certifications

Pressure Transmitter

Stable, precise, and engineered for demanding Industrial Conditions

Our pressure and differential-pressure transmitters are engineered for environments where long-term stability, temperature resilience, and reliable communication are essential. With intelligent sensing architecture, microprocessor-based compensation, and advanced HART capability, this platform delivers accurate, drift-resistant measurement across varied process conditions.

Request Your Free Quote Now

Precision Level Measurement Within Reach

Explore Our Pressure Transmitter

Designed for modern tank and vessel applications, these level meters combine dependable sensing with clear flow monitoring output. The product range supports consistent readings across diverse liquid phases, helping maintain operational continuity and informed decision-making.

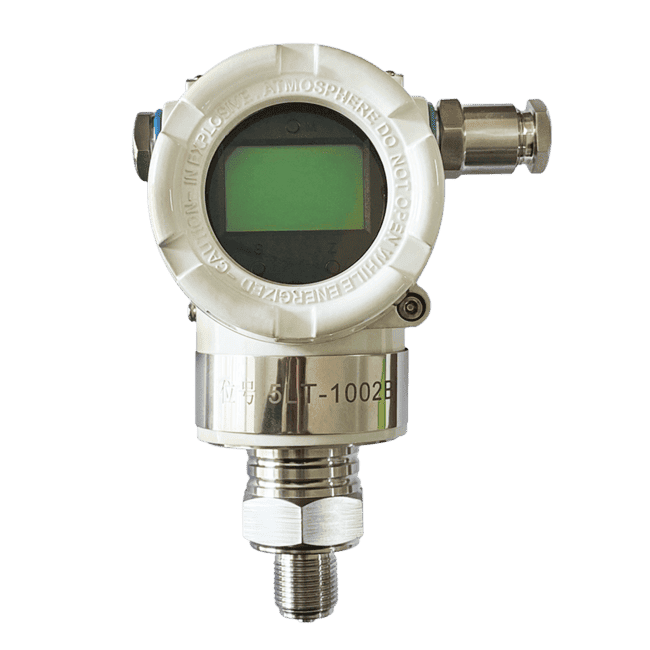

Gauge Pressure Transmitter

Stable gauge pressure measurement for pipelines, tanks, and general process control.

- Accuracy: ±0.1% / ±0.2%

- Stability: ±0.25% / 6 months

- Operating temperature: –40°C to 104°C

- Outputs: 4–20 mA + HART digital signal

- Overpressure protection: 2–5× rated range

Absolute Pressure Transmitter

Designed for applications requiring a non-zero reference point in variable ambient conditions.

- Accuracy: ±0.1% / ±0.2%

- Temperature deviation: ≤ ±1.0%

- Output signal: 4–20 mA + HART

- Electronics rated: –40°C to 85°C

- Optional local LCD configuration display

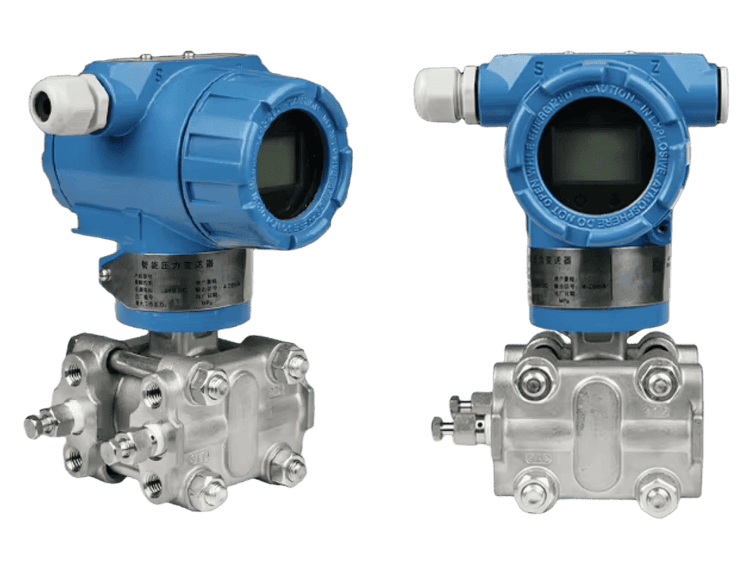

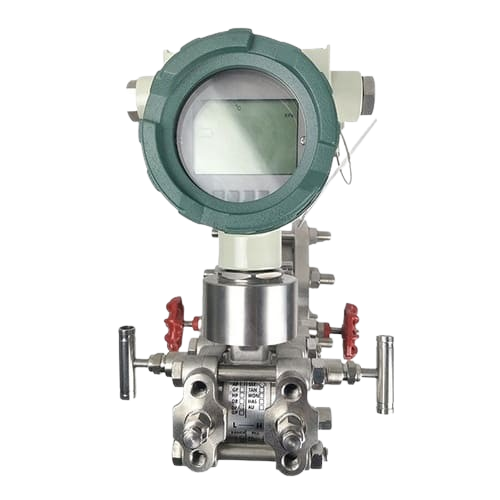

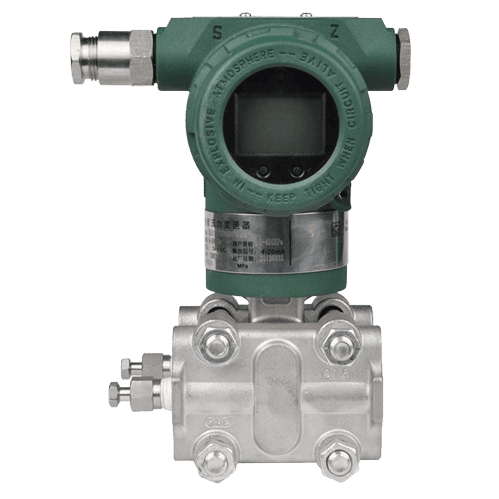

Differential Pressure Transmitter

For flow, level, filtration, and system differential monitoring.

- Accuracy: ±0.1% / ±0.2%

- Overpressure protection: 2–5× rated span

- Range ratio: up to 40:1

- Vibration resistance: ±0.05%/g at 200 Hz

- Suitable for orifice, venturi, and V-cone elements

High-Pressure Transmitter

Engineered for hydraulic circuits and elevated-pressure industrial systems.

- Accuracy: ±0.5–1.0%

- Operating range: –40°C to 85°C

- Burst pressure protection: > 2–5× span

- High-pressure compatible sensor structure

- Outputs: 4–20 mA + HART communication

High-Accuracy Transmitter

Enhanced accuracy variant for applications requiring refined resolution and low drift.

- Accuracy: ±0.1% / ±0.2%

- Long-term drift: ±0.25% / 6 months

- Adjustable damping: 0.2–32 s

- Digital linearity correction via microprocessor

- Suitable for precision process monitoring

Remote Pressure Transmitter

For high-temperature, corrosive, or isolated measurement points requiring remote diaphragm seals.

- Accuracy: ±1.0–1.5%

- Range ratio: 10:1 (20:1 optional)

- Zero calibration required after installation

- Suitable for level, vacuum, and DP flow

Main performance features

Design features that deliver measurable performance in real industrial environments.

Designed Through Rigorous Engineering Logic

Advanced sensing and compensation engineered for demanding environments

We design our pressure transmitters by aligning mechanical construction with digital processing capability. Capacitive sensing, refined diaphragm geometry, and intelligent compensation algorithms work together to maintain measurement accuracy when operating conditions shift.

Each stage—sensor modeling, compensation mapping, electronics design, and application validation—is executed to ensure stable accuracy, thermal resilience, and durable performance in real industrial environments.

High-Fidelity Sensing Design

Sensor cores are designed for minimal long-term drift, preserving measurement accuracy across extended operating periods.

Advanced Temperature Mapping

Digitized correction profiles stabilize output during rapid thermal variations common in pipelines and heating systems.

Digital Control & Algorithm Design

Embedded microprocessor algorithms manage linearity correction, drift reduction, damping response, and configuration data integrity.Operational Stress Testing

Transmitters undergo vibration, overload, and electrical stability tests to confirm reliability under industrial conditions.

Precision manufacturing tailored for industrial applications

Reliable measurement begins with advanced manufacturing & calibrated verification

Our pressure transmitters are built through controlled machining, careful assembly, and multi-stage calibration processes designed to preserve accuracy in real industrial conditions. Each sensing module undergoes thermal cycling, electrical interference checks, and multi-point pressure testing to confirm linearity and drift resistance. By combining exacting workmanship with rigorous validation, we deliver instruments that maintain measurement integrity throughout their service life.

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Precision Flow Measurement Starts Here

Discuss Your Application With Our Flow Specialists

Whether you’re handling clean liquids, viscous media, slurries, chemicals, or cryogenic fluids, our team can review your conditions and recommend the configuration that minimizes risk and maximizes measurement stability.

Request Technical Consultation