CE, SIL-3 & ATEX Certifications

Thermal Mass Flowmeter

Designed for stable, drift-controlled mass flow monitoring across air, nitrogen, oxygen, and industrial gas applications.

Our thermal flowmeters are designed to remain stable as flow, temperature, and load conditions change. By combining refined thermal sensing with robust signal handling, the instruments provide reliable data for compressed air systems, gas allocation, and environmental monitoring where measurement stability directly influences operational efficiency.

Request Your Free Quote Now

Thermal Mass Flow Solutions for Industrial Gas Systems

Industries & Applications

Purpose-Built Solutions for Accurate Flow Monitoring

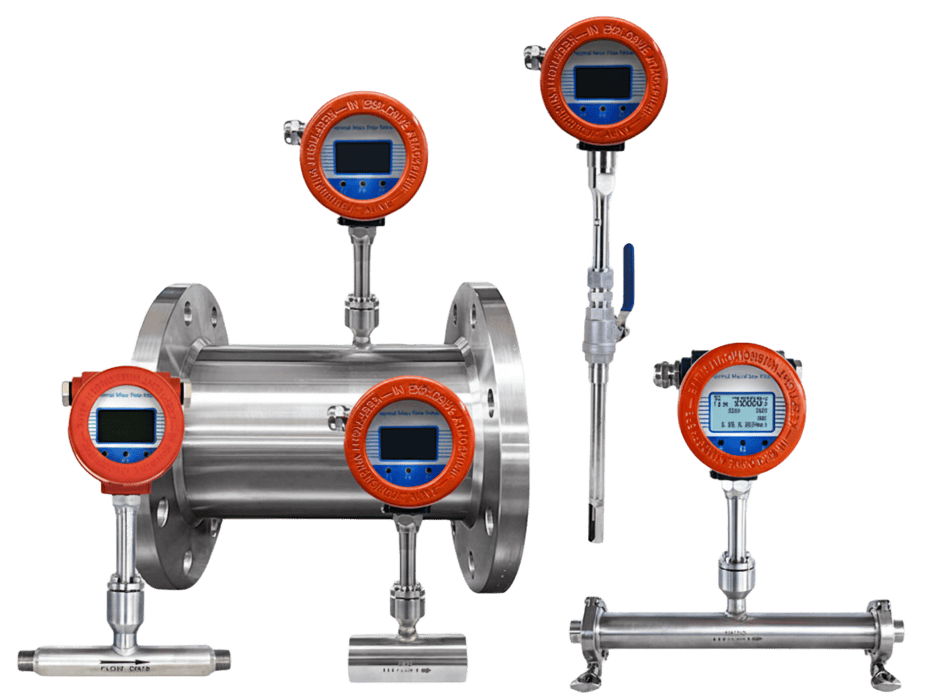

Explore Our Thermal Gas Mass Flowmeters

Our flowmeters are designed to support diverse industrial gas applications with consistent accuracy and stable long-term performance. Each model offers a specific installation style and sensing configuration, allowing engineers to choose the most suitable option for their pipeline, process conditions, and operational requirements.

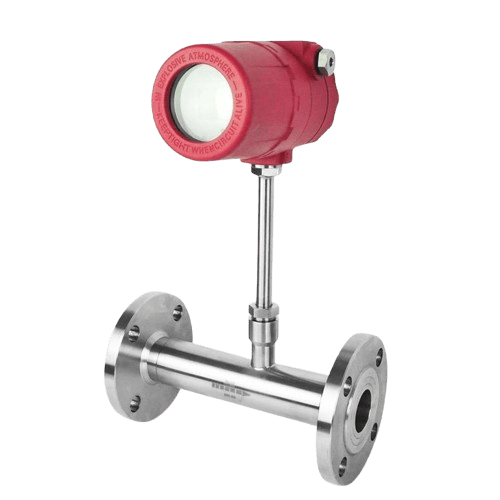

Inline Thermal Mass Flowmeter

Sealed inline structure optimized for stable thermal response in compressed air and utility gas lines.

- Accuracy: ±0.5% of reading

- Nominal diameter: DN15–DN2000

- Flow Velocity Range: 0.1–120 Nm/s

- Repeatability: ±0.25%

- Medium Temperature: –40°C to +220°C (standard)

- Multiple Output: 4–20 mA, RS-485 (MODBUS), and optional HART

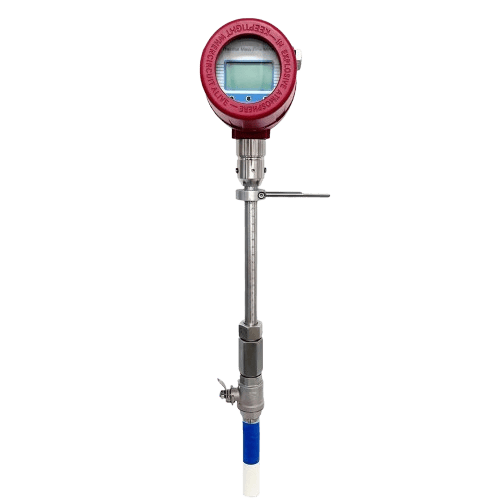

Insertion Thermal Mass Flowmeter

Direct mass measurement for large pipelines with wide turndown and low-velocity sensitivity.

- Accuracy: ±1% of reading

- Pipe Diameter: DN50–DN6000

- Flow Velocity Range: 0.1–120 Nm/s

- Medium Temperature: –40°C to +350°C

- Operating Pressure: Up to 6.0 MPa

- Output Signals: 4–20 mA, RS-485 (MODBUS or HART)

Main performance features

Design features that deliver measurable performance in real industrial environments.

Precision Flow Measurement Starts Here

Discuss Your Application with Our Flow Experts

Our Thermal Mass Flowmeters are fully customizable design, from specialized fluids, pipe size to standard specifications, our specialists work closely with you to create the perfect solution for your needs. Experience the difference of customized excellence today!

Request Technical ConsultationEngineering Innovation That Elevates Gas Measurement

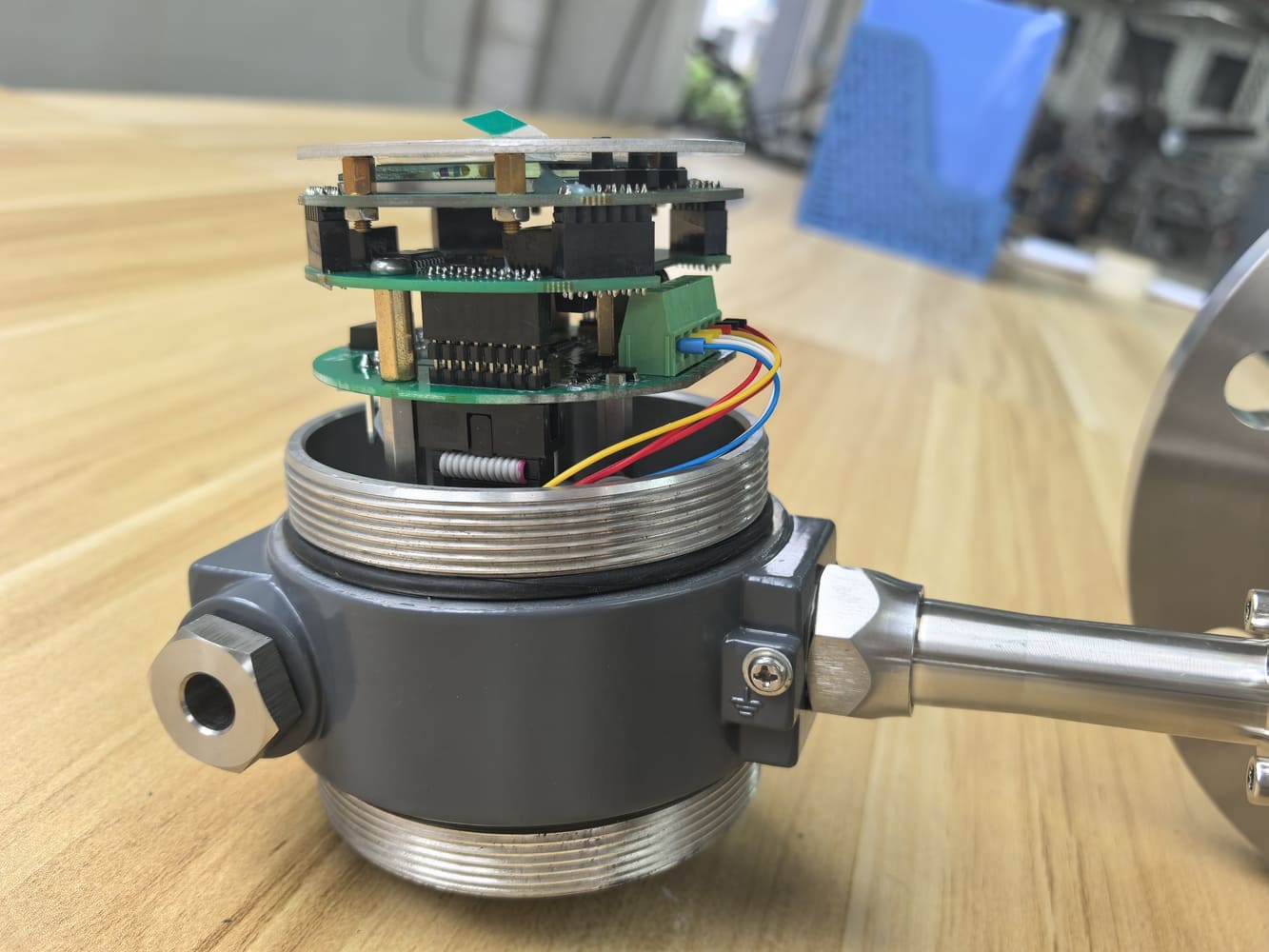

R&D Design Built on Thermal Response Mastery

Our thermal gas mass flowmeters are developed through a disciplined R&D process centered on thermal-differential behavior, material stability, and long-term sensing reliability. Using simulation, laboratory testing, and field validation, we refine our designs to maintain stable mass flow output under complex gas compositions, wide velocity ranges, and industrial environmental conditions.

Heat-Transfer Simulation Design

We model sensor heat-transfer profiles to refine thermal response curves, securing consistent mass flow calculations across operating ranges.

Precision Signal Regulation

Electronics and filtering logic are engineered to preserve signal clarity in the presence of vibration, electrical noise, or rapid load fluctuation.

Probe Structure Optimization

Mechanical and material refinements reduce drift, enhance corrosion resistance, and support long-term durability under high thermal stress.

Field-Condition Validation

Meters are validated through flowbench testing and extended on-site trials to confirm reliable performance in utility and process gas systems

Built With Precision, Verified With Discipline

Manufactured for Consistency, Built for Demanding Conditions

Our production process focuses on structural integrity, sensor stability, and electronics resilience. Each flowmeter is assembled using corrosion-resistant materials, tested for thermal response, and verified for long-term drift behavior. By combining machining precision with controlled calibration and environmental testing, we ensure consistent performance from installation through years of operation.

Operational Efficiency Through Low-Maintenance Design

Built to reduce service time, installation complexity, and long-term operating cost

From the sensor assembly to the transmitter electronics, every component is built for long-term reliability. The meter’s stable thermal-differential measurement reduces the need for recalibration, while its non-intrusive design lowers mechanical wear and maintenance effort. Over years of operation, these advantages accumulate—providing plants with a flow measurement solution that offers consistent performance at a lower total cost of ownership.

Get Started Now!A Picture's Worth a Thousand Words

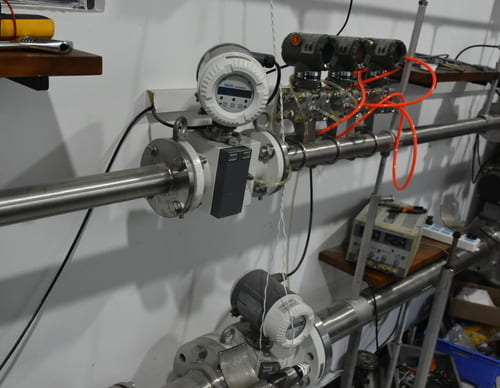

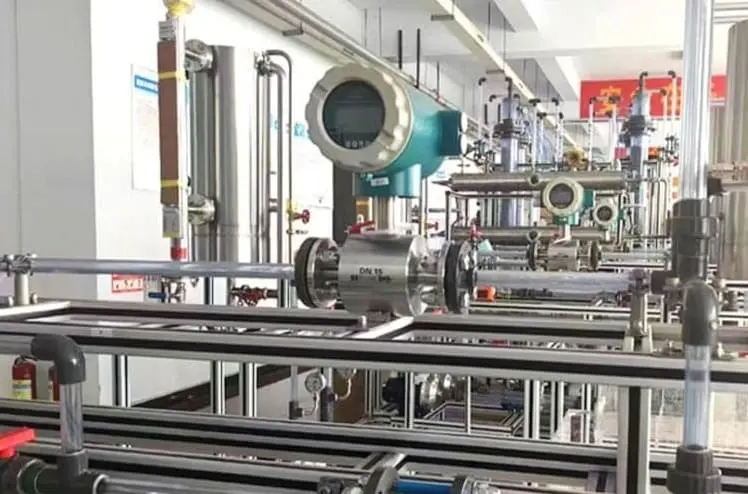

Installed in Working Plants Worldwide

Precision Flow Measurement Starts Here

Discuss Your Application With Our Flow Specialists

Whether you require specialized materials for aggressive fluids, non-standard pipe sizes, or integration with existing systems, our experienced engineering team ensures optimal performance of the precision flow meter for your unique application.

Request Technical Consultation