CE, SIL-3 & ATEX Certifications

Turbine Flowmeters

High-precision metering engineered for Gas & Liquid Measurement

Our turbine flowmeter is engineered with calibrated rotor dynamics, controlled bearing structures, and advanced signal processing to deliver dependable measurement across gas and liquid applications, can deliver stable, repeatable measurement for clean gases and liquids across chemical plants, gas distribution networks, energy systems, water treatment facilities

Request Your Free Quote Now

Industry-Leading Accuracy at Your Fingertips

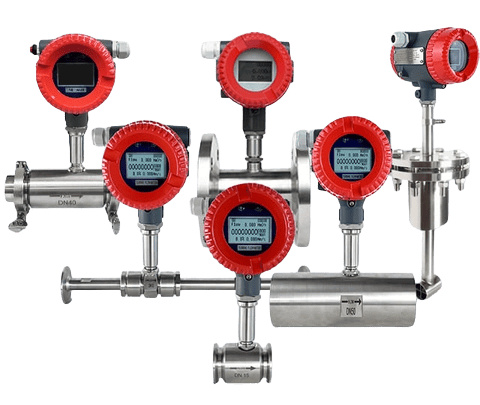

Explore Our Turbine Flowmeters

Our turbine flowmeter series includes several design variants to to match different pipe sizes, installation constraints, and medium characteristics.

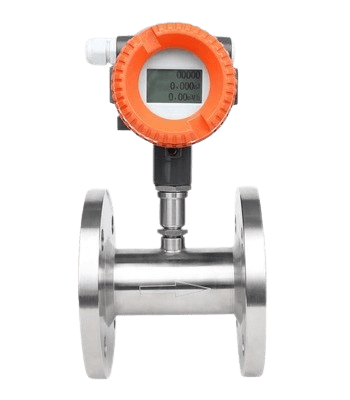

Liquid Turbine Flowmeters

Precision measurement for clean, low-viscosity liquids across process & utility lines.

- Accuracy: ±0.5–1.0%

- Repeatability: 0.05–0.2%

- Nominal diameter: DN4–DN100

- Medium: Water, solvents, alcohols, light oils

- Outputs: Pulse, 4–20 mA, RS-485, etc

Clamp-on Turbine Flowmeter

Non-intrusive turbine measurement for temporary or access-limited lines.

- Nominal diameter: DN4–DN100

- Installation: External clamp-on design

- Medium: Clean liquids

- Application: Commissioning checks, audits, temporary monitoring

- Output: Pulse / 4–20 mA

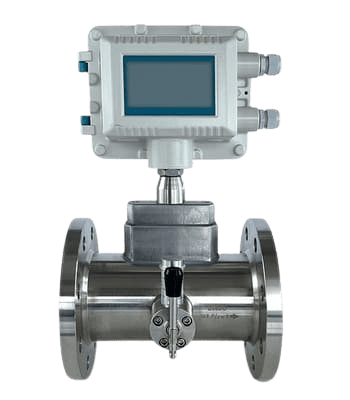

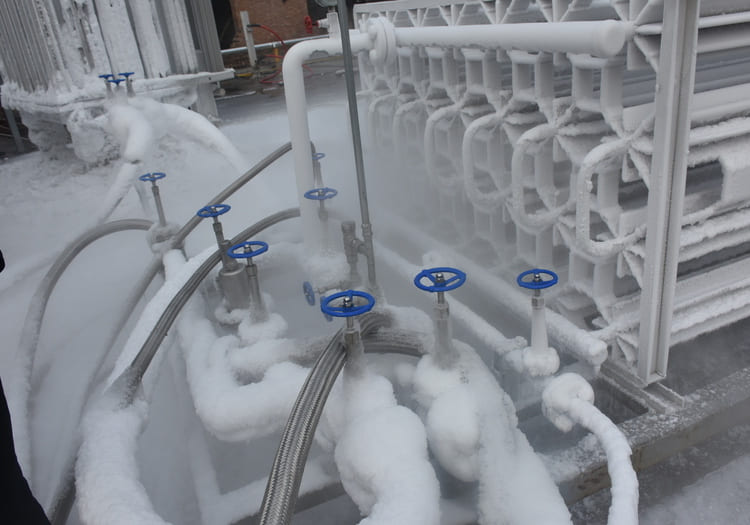

Gas Turbine Flowmeter

High-accuracy metering for natural gas, city gas, LPG, air, and inert gases.

- Accuracy: ±1.0–1.5%

- Range ratio: 10:1 (20:1 optional)

- Nominal diameter: DN25–DN300

- Medium: Natural gas, air, nitrogen, LPG, etc

- Outputs: Pulse, 4–20 mA, RS-485, etc

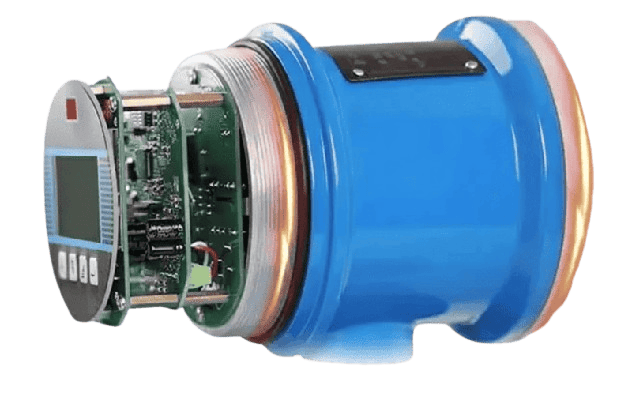

Insertion Turbine Flowmeters

Cost-effective solution for large pipelines and retrofit installations.

- Nominal diameter: DN150–DN2000

- Range ratio: Up to 20:1

- Output: Pulse / 4–20 mA

- Medium: Clean liquids or gases

- Installation: Fixed or hot-tap

Threaded Turbine Flowmeter

Compact turbine metering for small-diameter pipelines and OEM systems.

- Nominal diameter: DN4–DN40 (threaded

- Accuracy: ±1%

- Medium: Water, fuel, alcohols, chemicals,etc

- Output: Pulse or 4–20 mA

- Application: Skids, dosing systems, packaged equipment

Main performance features

Design features that deliver measurable performance in real industrial environments.

R&D capabilities

Engineered for Accuracy, Stability & Long-Term Reliability

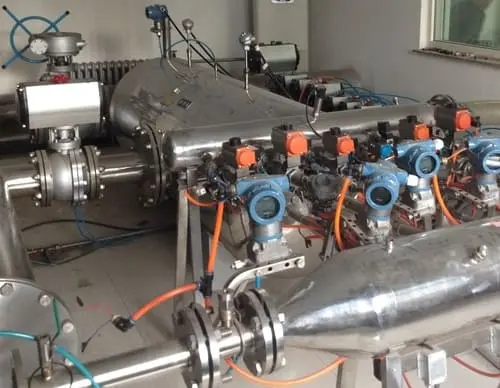

Our engineering work covers sensor design, rotor simulation, electronics development, and calibration algorithm refinement. We study rotor behavior through fluid-simulation tools, optimize pickups for signal clarity, and test electronics under electrical and thermal stress to ensure long-term stability in real plants.

Get an instant quotePrecision Manufacturing for Stable Long-Term Performance

Our manufacturing flow is designed to ensure rotor precision, mechanical stability, and consistent signal output. From machining to final calibration, every turbine meter undergoes controlled production steps that verify performance before shipment.

- CNC rotor machining and controlled polishing for dimension stability & low friction.

- Multi-point flow calibration across the operating range to verify linearity & K-factors.

- Environmental & electrical testing to confirm signal quality under temperature variation and EMI exposure.

- Seal, housing, and display checks performed on final assemblies to verify complete meter readiness.

Say Goodbye to Hidden Costs!

Optimize your operations cost with our solutions for long-term savings

Choose our turbine flow meters for an affordable solution that doesn’t compromise on quality. With low initial purchase cost and reduced maintenance requirements, you’ll experience lower operational costs and improved efficiency, delivering substantial long-term savings—making every measurement count toward your bottom line.

Get Started with a Free Consultation!Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

A Picture's Worth a Thousand Words

Trusted by Facilities Around the World

Not sure which model fits your system? Talk to an Engineer for expert guidance.

Whether you require specialized materials for aggressive fluids, non-standard pipe sizes, or integration with existing systems, our experienced engineering team ensures optimal performance of the precision flow meter for your unique application.

Contact Us for Tailored Solutions