CE, SIL-3 & ATEX Certifications

Ultrasonic Flowmeters

for Non-Intrusive, Accurate, and Versatile Flow Measurement

Accurate Flow Measurement at Your Fingertips

Explore Our Ultrasonic Flowmeters

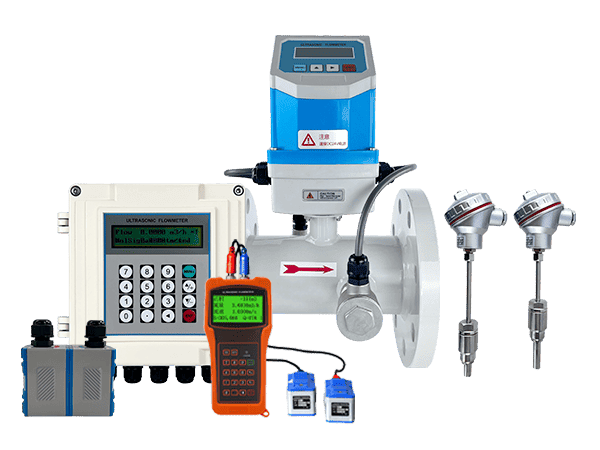

inline Ultrasonic Flowmeter

- Accuracy: <±1 %

- Nominal diameter: DN 10 – 600 mm

- Repeatability: 0.2 %

- Measurement period: 500 ms

- Medium flow velocity: 0.5 ~ 15 m/s

Clamp-on Ultrasonic Flowmeter

- Accuracy: ±1% of reading

- Pipe size range: DN15 ~ DN6000

- Repeatability / linearity: 0.15% / 0.5%

- Velocity range: 0 to ±30 m/s

- Measurement period: ~500 ms typical

Portable Ultrasonic Fowmeter

- Accuracy: < ±1%

- Pipe Diameter: DN15 ~ DN6000

- Velocity Range: 0 ~ ±32 m/s

- Repeatability: 0.2%

- Humidity Transmitter: 85% RH

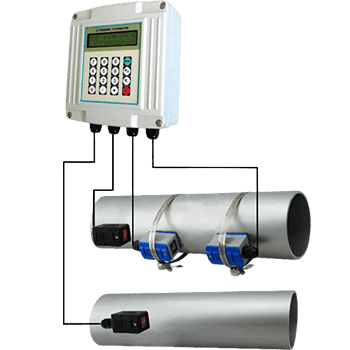

Wall-mounted Ultrasonic Flowmeter

- Accuracy: ±1% of reading

- Caliber: DN16 ~ DN6000

- Velocity range: 0 to ±10 m/s

- Operating temperature: −30 °C to +160 °C

- Flow direction: Bi-directional with net/pos/neg totalizing

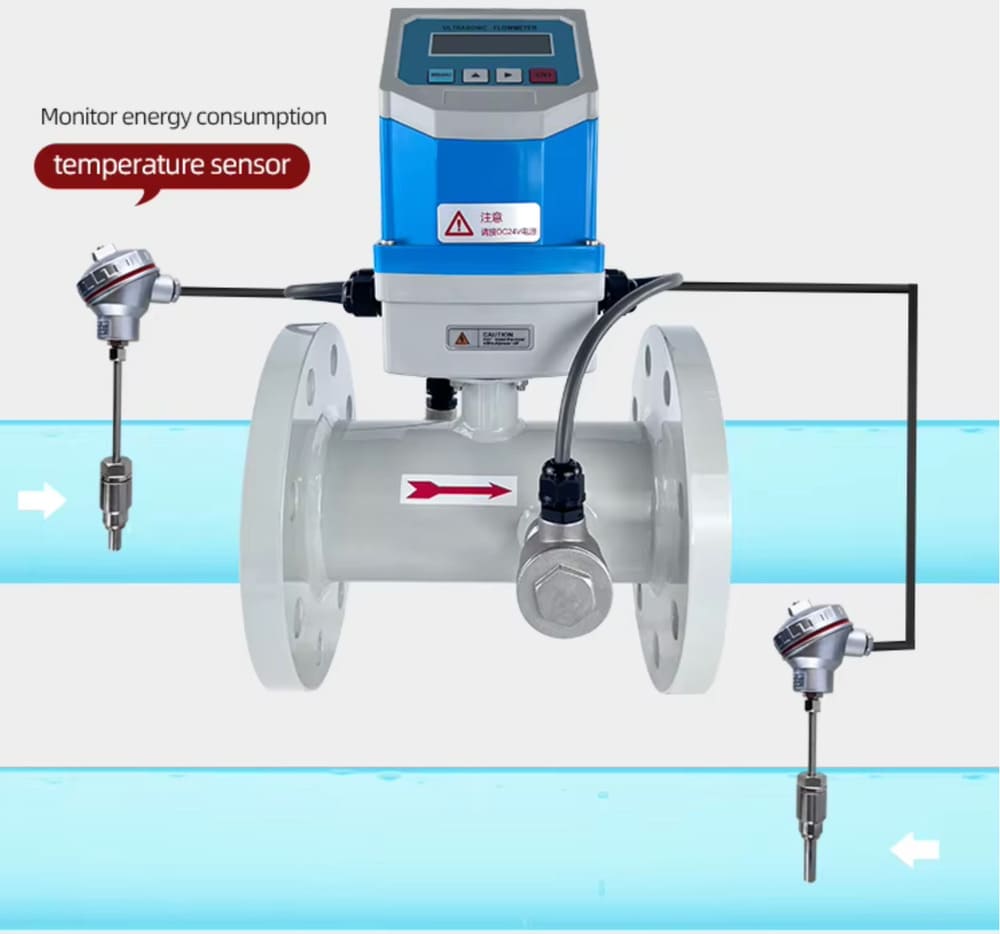

Ultrasonic BTU Flowmeter

- Accuracy: ±1.5%, ±2.0%. ±2.5%

- Caliber: DN100 ~ DN3000

- Flow Velocity: 0.1–10 m/s

- Pressure Range: 0.6 ~ 1.6 MPa

- Temperature Range: -25 ~ 150 ℃

Ultrasonic Open Channel Flowmeter

- Accuracy: ±0.5%, ±0.3% or ±0.2%

- Measuring distance (level): 0 to 3 m

- Measuring range: About 0.1 L/s to 10 m³/s

- Blind zone: 0.3 m to 0.5 m

- Communication: RS-485, Modbus protocol

Precision Flow Measurement Starts Here

Discuss Your Application with Our Flow Experts

R&D That Builds Stronger, Smarter Flow Measurement Solutions

Acoustic Path Optimization

Transducer placement, spacing, and beam alignment are refined through modeling and field validation to ensure stable signal transmission across different pipe materials, wall thicknesses, and surface conditions.

Precision Timing Algorithms

Our timing circuits evaluate microsecond-level transit differences using enhanced noise filtering, supporting accurate measurement even when liquid temperature, flow velocity, or pipe geometry introduce fluctuating signal behavior.

Coupling Surface Engineering

Contact surfaces and coupling interfaces are optimized for minimal attenuation, maintaining strong signal amplitude regardless of pipe age, coating thickness, or surface condition.

Algorithmic Flow Correction

Flow algorithms compensate for skewed velocity profiles and asymmetrical pipe conditions, supporting stable readings where hydraulic irregularities commonly degrade accuracy.

Manufacturing & Quality Control

Quality-Centered Manufacturing from Components to Final Calibration

Built to Reduce installation complexity, Maintenance and Long-Term Spending

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

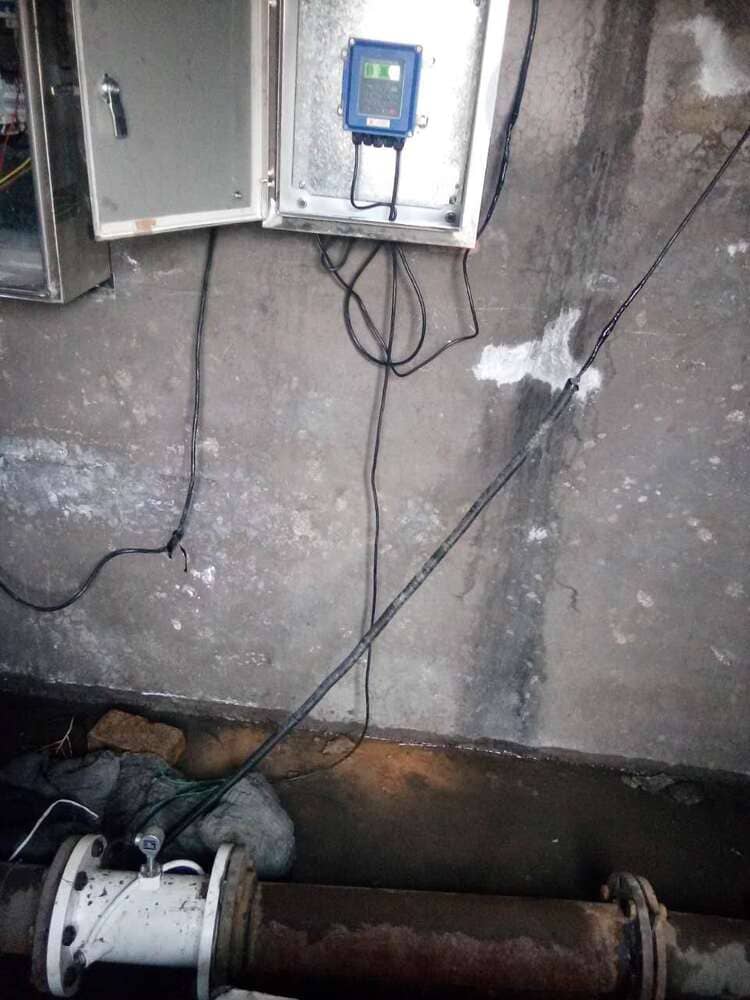

Trusted by Industrial Users in 66+ Countries

Application Stories

.jpg)

.webp)

-1.jpg)