Ultrasonic BTU Flowmeter

Approved by:CE, SIL-3, ATEX Explosion-proof certification

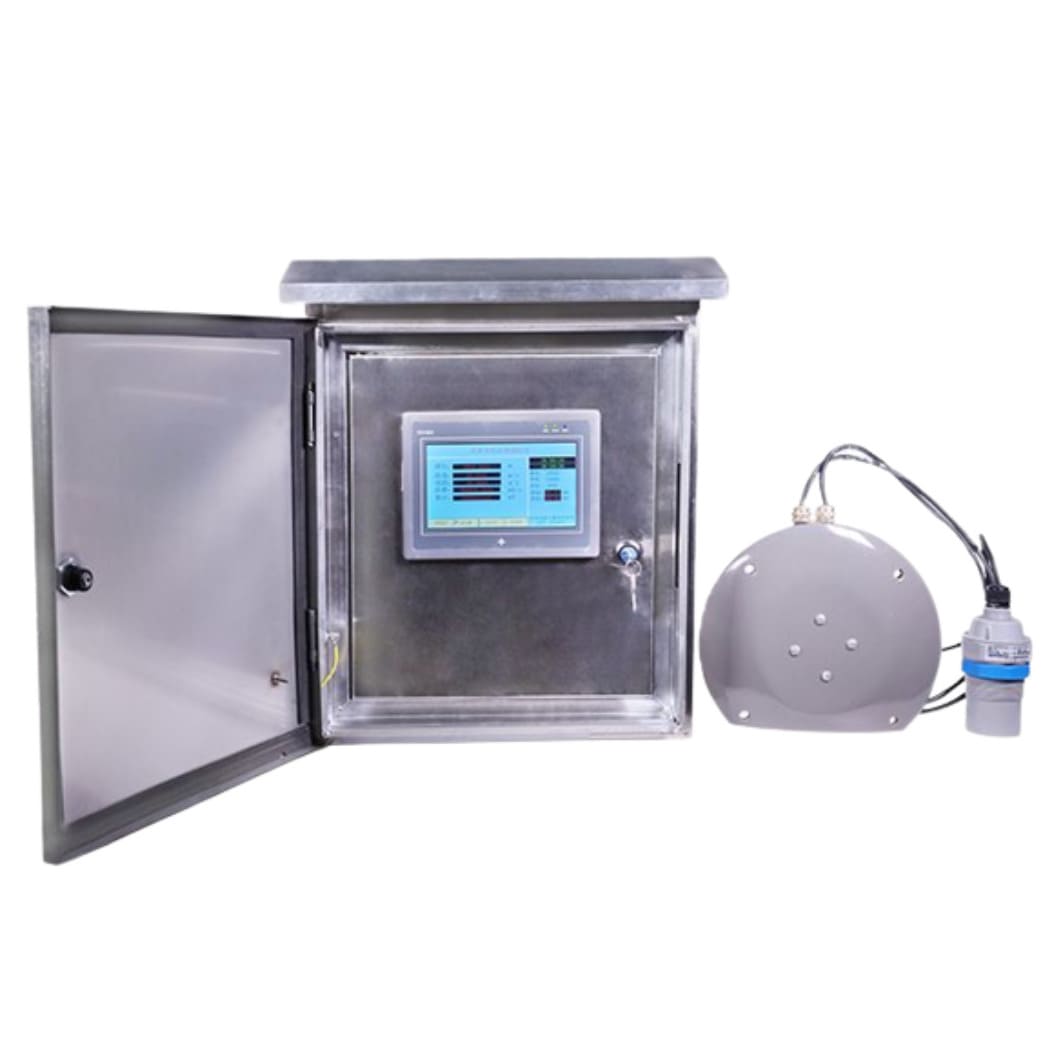

The Ultrasonic Open Channel Flowmeter provides a clean, efficient solution for monitoring open-channel flows in environmental and industrial applications, This is a high-accuracy, non-contact instrument for continuous flow measurement in open channels, weirs, and flumes.

Using ultrasonic technology, it measures liquid levels above a weir or flume without touching the fluid—eliminating blockages, reducing maintenance, and ensuring stable readings even in difficult water conditions.

Operators gain clear real-time readings, totalized data, and automatic logging without the need for complicated maintenance. With durable IP-rated protection, multi-signal outputs, and built-in surge protection, it’s engineered for continuous duty in wastewater plants, drainage systems, irrigation channels, and industrial effluent lines—where accuracy and reliability truly matter.

-

Non-contact ultrasonic sensing — Measures level above the stream, so there’s no fouling, zero head loss, and longer sensor life.

-

Built-in weir/flume math — Select Parshall, rectangular, or triangular weirs, so setup is fast and results follow known standards.

-

Instantaneous + totalized flow display — See live flow and accumulated totals on the panel, so operators get answers at a glance.

-

Data retention on power loss — Internal memory protects totals and settings, so records aren’t lost during outages.

-

4–20 mA + RS-485 (Modbus) — Tie into PLC, SCADA, or data loggers easily, so compliance reporting is straightforward.

-

Lightning protection & industrial design — Built-in surge protection and rugged housing, so it survives real-world sites.

-

Millimeter-level resolution — 1 mm level resolution and stable algorithms, so low-flow changes are captured clearly.

-

Wide flow range — From small channels to high-throughput discharge, so one meter covers varied sites.

-

Simple menu commissioning — Height set and quick calibration steps, so technicians can finish setup in minutes.

-

Maintenance-friendly — Sensor mounts above water and stays clean, so routine work is minimal.

-

Measuring range (flow): About 0.1 L/s to 10 m³/s (depends on weir/flume type and size)

-

Cumulative flow range: Up to 999999999999 m³

-

Measuring distance (level): 0 to 3 m (typical model)

-

Blind zone: 0.3 m to 0.5 m (sensor must be installed higher than this)

-

Level resolution: 1 mm

-

Level accuracy: ±0.3 % of measuring distance

-

Flow accuracy: About 1 % (depends on weir/flume and correct installation)

-

Supported channel structures: Parshall flume, rectangular weir, triangular/V-notch weir (national/industry standard sizes)

-

Display: Built-in LCD, shows instantaneous flow and accumulated flow

-

Analog output: 4–20 mA (range can be set to match full-scale flow)

-

Digital output / communication: RS-485, Modbus protocol

-

Power supply: DC 12 V / DC 24 V / AC 220 V (depending on model), with lightning protection

-

Ambient temperature: −20 °C to +60 °C (instrument)

-

Protection level: IP65 (typical instrument/sensor housing)

-

Installation position: Above centerline of channel or in stilling well, upstream of the weir/flume

-

Supported flow units: m³/h, L/h, t/h, m³/min, L/min, m³/s, L/s

-

Output setting: 4 mA corresponds to 0 (or min), 20 mA corresponds to set upper range

-

Data storage: Built-in memory for instantaneous and total flow, retains data after power-off

-

Typical power consumption: <3 W

-

Optional functions (depending on version): Relay outputs, SD/USB data collection, mini printer, GPRS/GPS data transfer

-

Install the ultrasonic sensor vertically above the measuring point (center of channel or stilling well) and make sure the sound path is not blocked.

-

The sensor must be installed higher than its blind zone (usually ≥300–500 mm from the highest water level).

-

The weir or flume must meet the standard dimensions (smooth inner wall, correct throat width, correct crest height). Inaccurate weir size = inaccurate flow.

-

The instrument should be installed upstream of the weir/flume and in a place with stable, non-turbulent flow.

-

Avoid foam, floating debris, and strong surface turbulence; if present, install a stilling/wave guide tube.

-

After installation, perform “height setting” — enter the actual distance from the probe face to the channel bottom or reference plane.

-

Set the correct weir/flume type in the menu so the instrument uses the right flow formula.

-

Keep signal/power cables away from high-voltage and inverter cables; if long cables are used, use shielded cable.

-

For outdoor use, put the main instrument in a protective box (stainless or FRP) to prevent sun/rain.

-

Clean the sensor face if there is sludge or scaling to maintain good signal reflection.

-

Wastewater plant discharge — Final effluent compliance monitoring at outfalls.

-

Industrial effluent — Factory discharge oversight for environmental reporting.

-

Sewer overflows / stormwater — CSO/SSO points and storm channels where no intrusion is allowed.

-

Irrigation and canals — Open canal allocation, distribution, and loss audits.

-

Water treatment works — Raw water intakes and wash-water channels.

-

Mining and process sites — Settling pond outlets and plant drainage channels.

-

Hydrometric stations — Temporary or permanent monitoring of natural/open channels with standardized structures.