CE, SIL-3 & ATEX Certifications

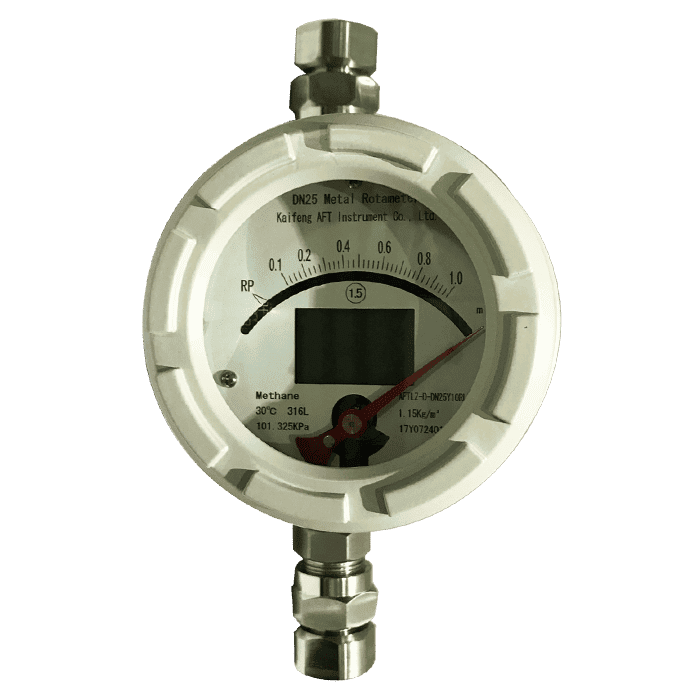

variable area flow meter

Designed for stable, drift-controlled mass flow monitoring across air, nitrogen, oxygen, and industrial gas applications.

We develop variable-area flowmeters that offer straightforward, dependable measurement in real-world operating environments. By combining controlled float geometry with durable tube construction, our rotameters give operators clear visibility into process behavior, supporting stable plant performance and consistent system oversight.

Request Your Free Quote NowPrecise Flow Monitoring, Made Accessible

Explore Our variable area flowmeter Series

Built on proven variable-area principles, our rotameters deliver consistent, easy-to-read flow monitoring without the need for power or complex infrastructure. Designed for liquids, gases, and utility services, they offer a practical and durable solution for continuous process oversight.

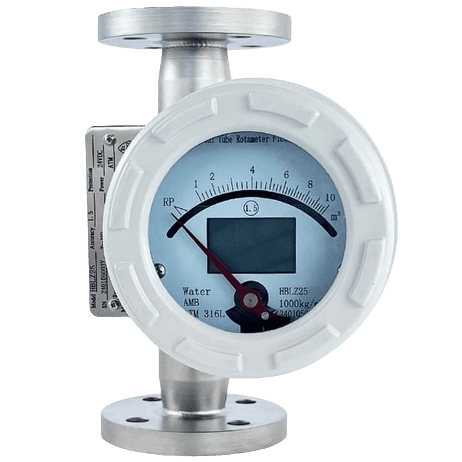

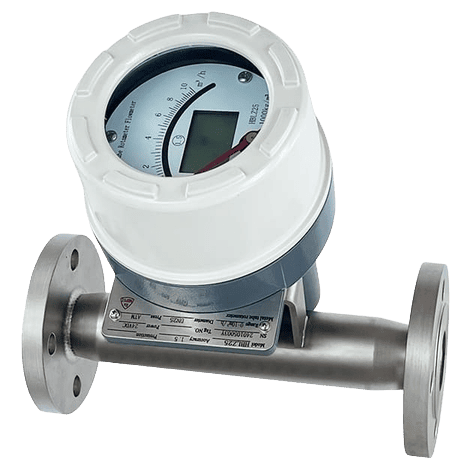

Standard Rotameter

Reliable all-metal variable-area flowmeter for general industrial use, providing stable measurement of liquids, gases, and steam with minimal maintenance requirement

- Accuracy: ±1.0%

- Range Ratio: 10:1 (standard)

- Operating Temp: −30°C to +120°C

- Protection Rating: IP65 / IP67

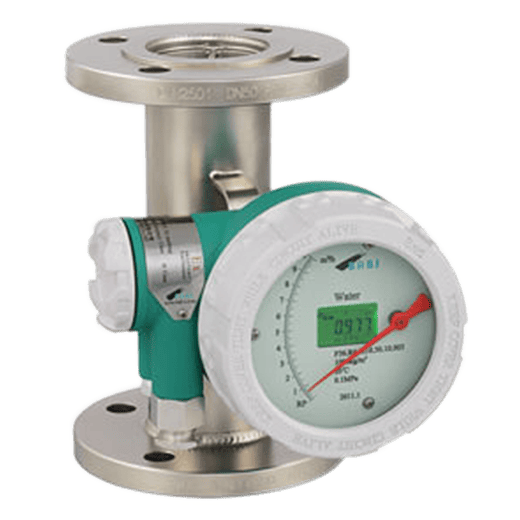

Remote-Transmission Rotameter

All-metal rotameter with integrated transmitter delivering 4–20 mA or HART output for PLC/DCS systems requiring remote flow monitoring.

- Accuracy: ±1.5%

- Repeatability: 0.2–0.5%

- Ambient Temp:−30°C to +60°C

- Power Supply: 24 VDC or 3.6 V

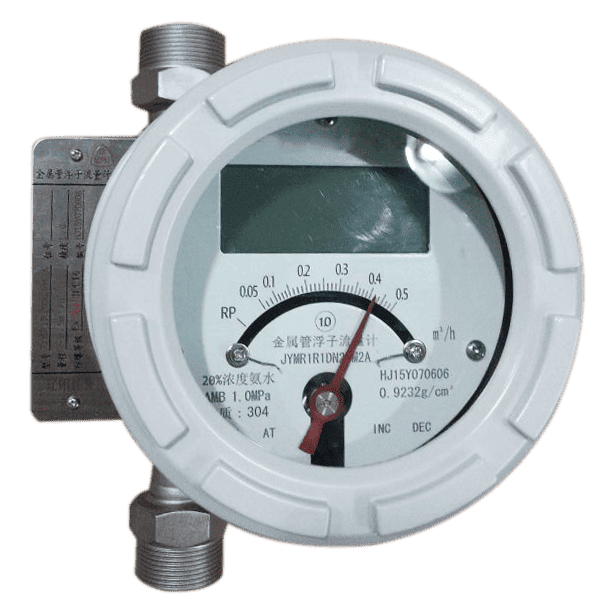

Anti-Corrosion Rotameter

Design with PTFE-lined tube and corrosion-resistant components designed for acids, alkalis, and aggressive chemical media in challenging process environments.

- Accuracy: ±1.5% ~ ±2.5%

- Wetted Material: PTFE lining

- Medium Temp:≤90°C for PTFE type

- Viscosity Capability: ≤5 mPa

High-Temperature Rotameter

Heat-resistant rotameter engineered for high-temperature liquids, gases, and steam, ensuring stable performance in demanding thermal process conditions.

- Accuracy: ±1.5%

- Medium Temp: up to 300°C

- Ambient Temp: up to +120°C

- Max Pressure: 1.6–4.0 MPa

High-Pressure Rotameter

Reinforced rotameter designed for high-pressure liquids and gases, providing reliable flow measurement in pressurized industrial and energy applications.

- Accuracy: ±1.5%

- Max Pressure: Up to 20 MPa

- Range Ratio: 10:1

- Pressure Range: 1.6 ~ 1.6 MPa

Explosion-Proof Rotameter

Explosion-proof rotameter built for hazardous areas requiring intrinsic safety or flameproof protection, ensuring safe flow measurement in explosive atmospheres.

- Accuracy: ±1.0%

- Ambient Temp: −40°C to +120°C

- Output: 4–20 mA, pulse, alarms

- Explosion-Proof: Exia II CT1–T6

Heating-JacketedRotameter

Rotameter with an external heating jacket to maintain medium temperature, ideal for viscous, crystallizing, or temperature-sensitive process fluids.

- Accuracy: ±1.5%

- Temperature Capability: up to 300°C

- Range Ratio: 10:1

- Body Material: SS304 / SS316L

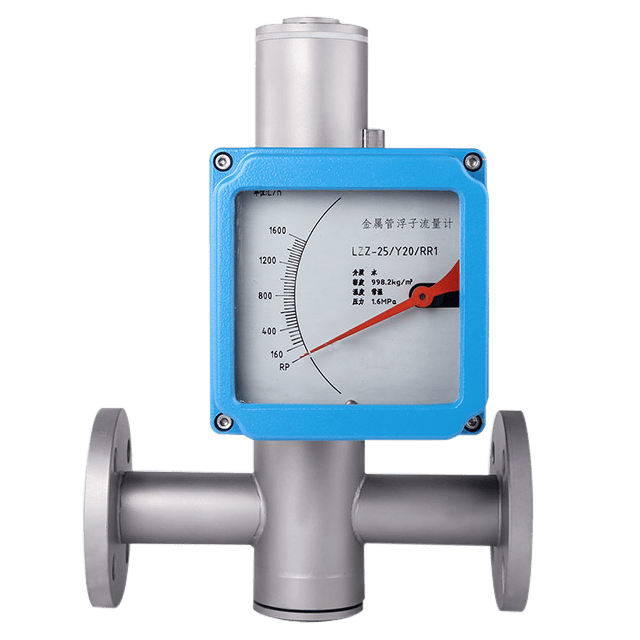

Top–Bottom Connection Rotameter

Featured with top-bottom piping configuration for vertical installations requiring flexible process connections.

- Accuracy: ±1.5%

- Installation: Vertical or horizontal

- Medium: Liquids, gases, steam

- Connection Type: Flange / Thread

Main performance features

Design features that deliver measurable performance in real industrial environments.

Where Mechanical Innovation Meets Measureme

Precision Design Guided by Applied Engineering

Our rotameter development focuses on the mechanical interactions that define stable level indication: float geometry, tube shaping, magnetic coupling, and scale linearity. Each design iteration is validated through controlled testing to ensure smooth float movement, predictable response under load changes, and long-term stability in demanding environments. This R&D framework allows us to keep the instrument mechanically simple while achieving reliable performance across liquid, gas, and steam applications.

Optimized Float Geometry

Float shapes are engineered to maintain stable rise characteristics and reduce oscillation across the operating range.

Float Mass Calibration

Float weight and contour are optimized to balance response speed with reading stability under real-world conditions.

Magnetic Coupling Control

Magnetic systems are engineered to transmit float position smoothly while resisting external interference.

Dynamic Load Testing

Meters undergo simulated variable-load testing to confirm response stability across full operating ranges.

Manufactured for Accuracy, Verified for Trust

Manufacturing Excellence Backed by Rigorous Multi-Point Calibration

Our rotameters are built through a combination of precision machining and targeted inspection at each production stage. Tube dimensions are verified for concentricity and smooth internal finish, floats are machined to controlled weight and geometry tolerances, and magnetic coupling components are inspected for signal consistency. Flow scales are validated using certified calibration equipment to ensure readings remain accurate over the full range.

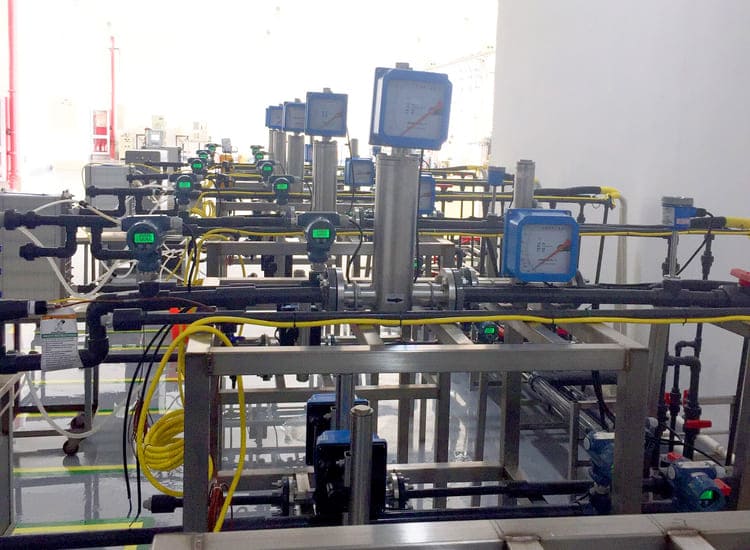

A Picture's Worth a Thousand Words

Field-Tested in Real Production Conditions

Precision Flow Measurement Starts Here

Not sure which model fits your system? Talk to an Engineer for expert guidance.

Share your flow range, medium characteristics, and pipeline details, our team helps evaluate your technical parameters and service environment to identify the right rotameter for your process.

Request Technical Consultation