CE, SIL-3 & ATEX Certifications

Liquid Level Indicator

Engineered for Stable, Continuous Measurement Across Industrial Tanks and Vessels

Our liquid level meters are designed to provide precise, repeatable measurements that support safe storage, consistent process control, and reliable fluid management. Measurement stability is maintained even as conditions shift, enabling users to make informed operational decisions and protect equipment performance.

Request Your Free Quote NowPrecision Level Measurement Within Reach

Explore Our Liquid Level Indicator

Designed for modern tank and vessel applications, these level meters combine dependable sensing with clear flow monitoring output. The product range supports consistent readings across diverse liquid phases, helping maintain operational continuity and informed decision-making.

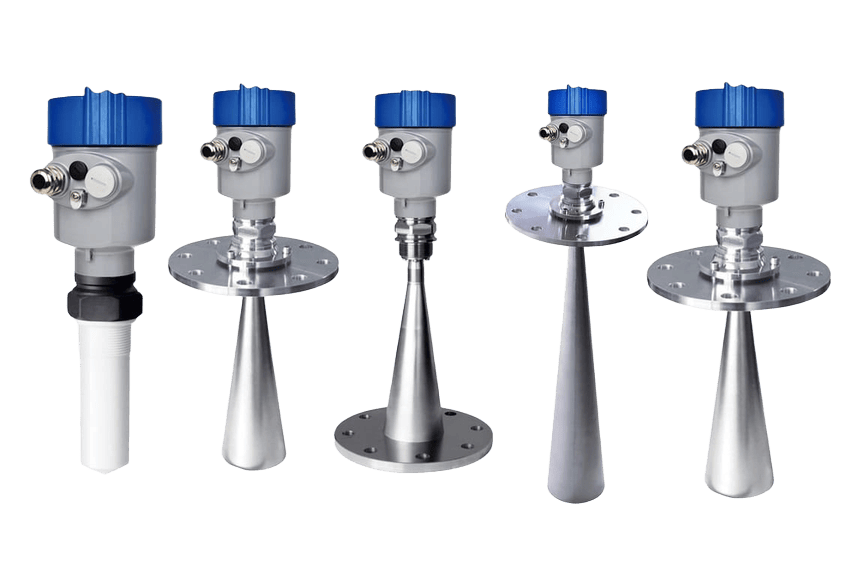

26G Pulse Radar Level Meter

Durable radar design providing consistent liquid level data in harsh tank environments with high temperature, vapor, or dust.

- Accuracy: ±3 ~ 5 mm

- Frequency: 26 GHz

- Measuring Range:Up to 30 m (model dependent)

- Process Temperature: –40°C to +250°C

- Housing Protection: IP65 / IP67

80G Pulse Radar Level Meter

80 GHz FMCW radar level meter is engineered for precise level measurement in demanding liquid and bulk-solid applications.

- Accuracy: ±0.02% F.S.

- Frequency: 80 GHz

- Beam angle: Approx. 3°

- Measuring range: 0.08–150 m

- Blind zone: Approx. 0.08 m (8 cm)

- Process pressure: −0.1 to +2.0 MPa

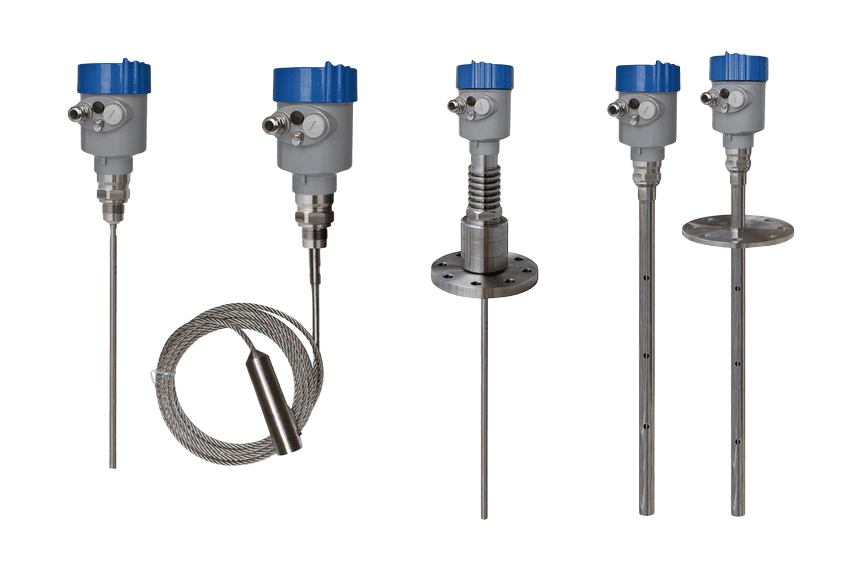

Guided Wave Radar Level Meter

Guided wave radar suited for liquids, viscous media, and interface layers, ensuring dependable measurement in complex tank conditions.

- Accuracy: ±5 ~10 mm (model dependent)

- Measuring Range: Up to 30 m (cable type)

- Process Temperature: –40°C to +250°C

- Process Pressure: up to 40 MPa

- Explosion-Proof Rating: Exd / Exia IIC T6

Main performance features

Design features that deliver measurable performance in real industrial environments.

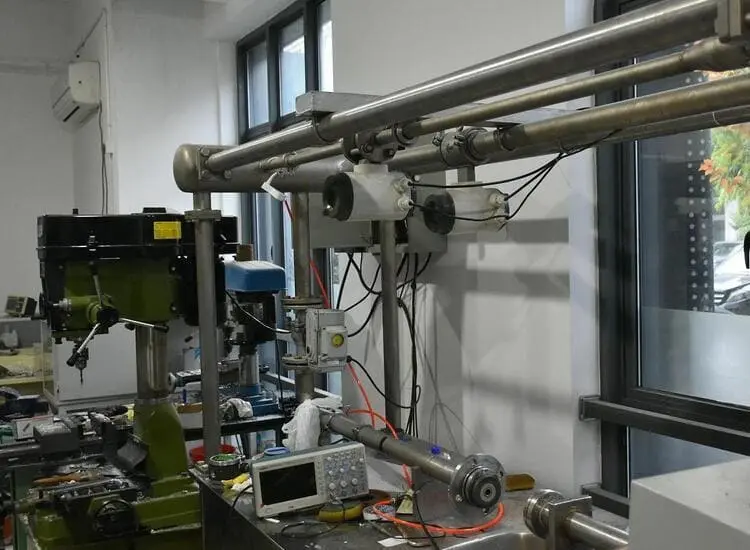

Engineering the Future of Liquid Level Measurement

Purpose-Built Innovation for Industrial Level Monitoring

Our R&D team develops and tests proprietary algorithms capable of recognizing weak echoes, filtering multi-path interference, and stabilizing measurements in foam, vapor, and turbulence. Each probe type—whether cable, rod, or coaxial—is optimized through structural simulations and material studies to ensure reliable performance under pressure, temperature, and corrosive load. By integrating hardware refinement with algorithmic intelligence, we deliver instruments engineered to maintain accuracy where process conditions fluctuate and installation spaces are constrained.

Application-Driven Design

We simulate liquid turbulence, foam formation, vapor layers, and tank geometry effects to guide critical design choices and eliminate measurement blind spots.

Sensor Algorithm Optimization

Each level measurement algorithm is refined through iterative testing to strengthen signal recognition, minimize false echoes, and maintain stable output across changing liquid phases.

Signal Filtering Architecture

Our team develops filtering logic that strengthens echo recognition, suppresses background noise, and stabilizes output under rapidly shifting operating conditions.

Material Durability Evaluation

All structural and sealing materials are assessed under pressure, temperature, and corrosive media exposure to ensure sustained durability in real-world use.

Built on Precision, Proven in the Field

Advanced Manufacturing & Calibration Processes for Reliable Liquid-Level Measurement

Our manufacturing program integrates precision machining, advanced assembly techniques, and multi-point calibration to ensure stable, repeatable level readings. Each Liquid Level Indicator is individually verified using traceable calibration standards, ensuring that its output remains consistent under variable tank conditions, liquid properties, and process temperatures.

Precision Flow Measurement Starts Here

Discuss Your Application with Our Flow Experts

Selecting a level meter isn’t just about choosing a model—it’s about ensuring it performs accurately under your real operating conditions. Our technical team analyzes your application requirements and identifies the most suitable configuration for your tank, medium, and control system.

Request Technical Consultation